Famsun Group Co., Ltd.

http://en.famsungroup.com/

Famsun Group Co., Ltd.

About company

Office & Factory

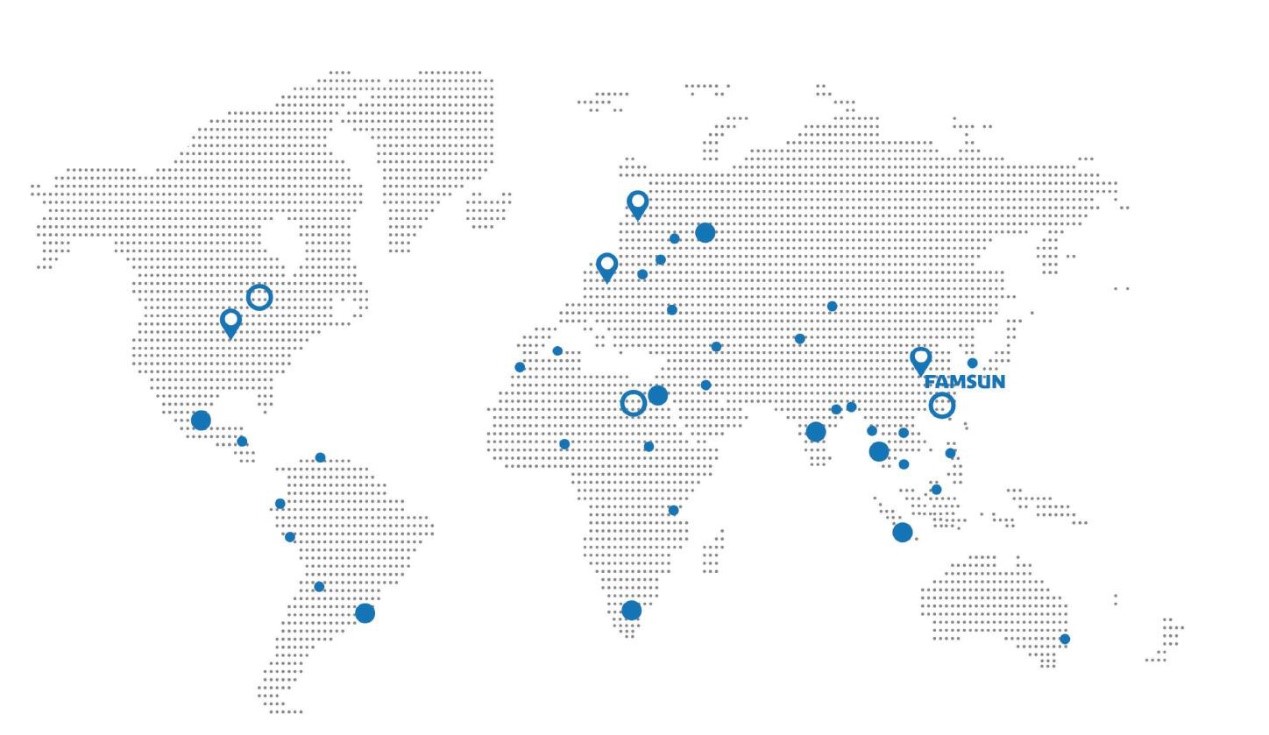

Global Presence

Company introduction

FAMSUN Group Co. Ltd., headquartered in Yangzhou, China, is a global technology partner and the integrated solution provider of plant, equipment and services in feed manufacturing, grain milling, grain handling and storage, oilseed processing, food processing, steel structure construction and industrial automation.

FAMSUN has over 2,800 employees, including 900 technicians and engineers. Backed by its strong R&D capabilities, FAMSUN has developed more than 120 series (700 models) of quality feed and grain processing machines and is capable of delivering a wide range of turnkey projects from farm to table and in associated industries.

FAMSUN operates 5 production sites as well as over 50 agencies, sales & service stations, and spare parts warehouses around the world. FAMSUN has successfully completed over 8600 referenced projects in more than 140 countries.

Our vision is to provide optimal technology solution and make life better for all. We value innovation, hard work, dedication, integrity, quick response and team work.

FAMSUN Pet Food division is committed on machinery research, manufacturing, project engineering, factory construction and integrated solutions in pet food industry, create values for customers. As a leading integrated solution provider in pet food industry, FAMUSN undertakes pet food (dry food, semi-moist, extruded treats) and cat litter turn-key project.

Our corporate leads the market by technology, with experienced elite team and European & USA technical experts, through continuous innovation, to provide customers with professional, safe, systematic extruded pet food production solutions, customized environment-friendly and intelligent factory with high standards, high quality, high efficiency. We won the trust and praise from our partners/customers worldwide.

8600+ referenced projects in 140+ countries 50+ agencies, sales & service stations and spare parts warehouses worldwide closed to customers 5 production bases, one in Egypt and five in China, total 74.07 hectares of manufacturing and distribution capacity 2800+ employees work in sales, customer service, engineering, R&D, production and logistics More than 5% of annual revenue invested in R&D every year Equipment is marked by CE and ATEX sym.

Products

Company News

Extrusion

Extrusion

1+ MIN

10/11/2023

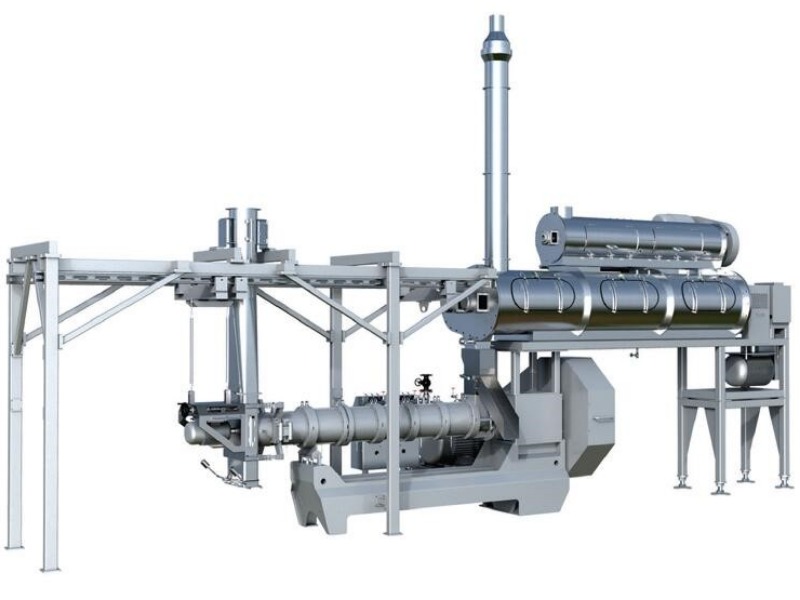

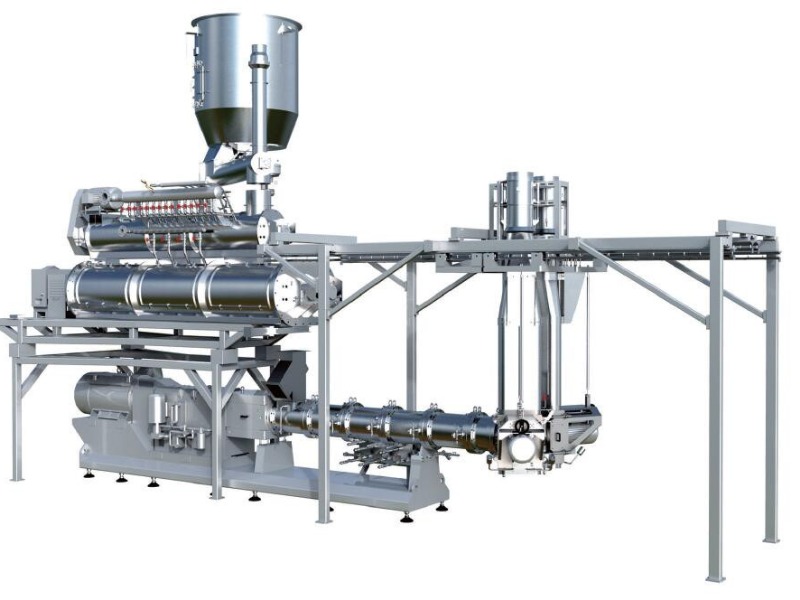

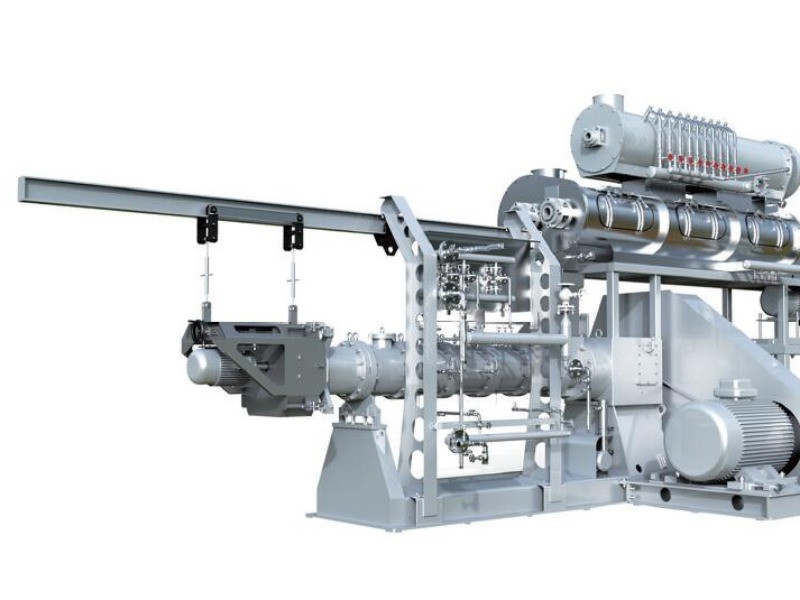

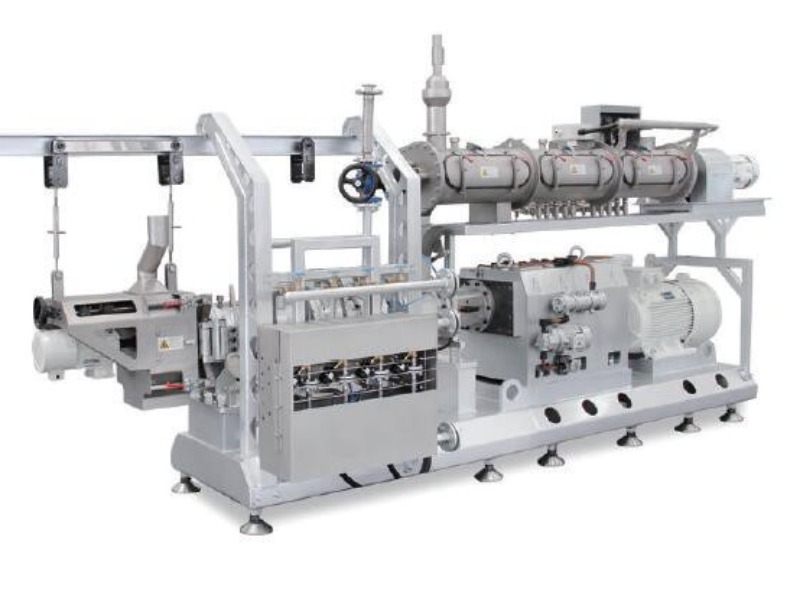

Famsun SJPS Series Twin-screw Extruder

FAMSUN Pet Food division is committed on machinery research, manufacturing, project engineering, factory construction and integrated solutions in pet food industry, create values for customers. As a leading integrated solution provider in pet food industry, FAMSUN undertakes pet food (dry food, semi-moist, extruded treats) and cat litter turn-key project. FAMSUN leads the market by technology, with experienced elite team and European & USA technical experts, through continuous innovation, to provide customers with professional, safe, systematic extruded pet food production solutions, customized environment-friendly and intelligent factory with high standards, high quality, high efficiency. They won the trust and praise from their partners/customers worldwide. The SJPS SERIES TWIN EXTRUDER is one of the highly efficient pet food extruders in Famsun's portfolio. Specially designed for formulations with a high content of fresh meat, we detail some of its advantages for pet food producers: Easy operation PLC and touch screen for convenient control; by-pass provided for avoiding blockage; easy operation, precise and reliable. High efficiency Optimal chamber groove and screw flight profiles, minimum SME input; efficient DDC conditioner and jacketed barrel with stabilized and facilitated extrusion, maximum energy utilization; unique suspending cutter, adjustment without down time. More flexibility Modularized barrel and screw structure with many add-ons, adaptable to varied high-fat or -moisture formulations; controllable temperature, pressure and density, minimizing reconfiguration acquired. You are invited to know more about FAMSUN PRODUCTS. Source: All Pet Food

Extrusion

Extrusion

4+ MIN

25/04/2022

FAMSUN Pet Food Plant Solution: Creating Life’s Simple Happiness at Industrial Scale

Living in a world that becomes ever more complicated and accepting that the pandemic will be part of today's life for years, many people help themselves become happy again by connecting with simple things like cats and dogs.

Life accompanying beloved pets brings many benefits to pet owners: from physical health to mental wellbeing. That is why the population of pet owners rises continuously amid COVID-19. And that is also the reason why FAMSUN and pet food producers worked hard to bring modern industrial pet food production systems around the world in the past years - serving the needs of millions of pets and pet owners and protecting what's good in life through health, nutritious and tasty pet food.

Innovation: Driving changes for better

Pet parents today care more about the nutrition, health, and well-being available for their pets. For example, nutritious and fresh-ingredient food such as high fresh meat products is a popular splurge item. Many owners are willing to pay extra for innovative choices that can solve allergies, picky eating habits, immune issues. Some are willing to pay extra for 'green' products that are sourced and produced responsibly and are aligned with their family sustainable actions.

At FAMSUN, we move fast to innovate and provide competitive, sustainable, and tailored pet food processing solutions that help producers and investors to seize new market chances and become differentiated in the marketplaces. Our experts of FAMSUN R&D institutes in the USA, Denmark, and China, who have dedicated themselves to the pet food industry for decades, are constantly working on innovations to increase pet food plants' capability and make them process smarter, more efficient, and more sustainable.

FAMSUN has been researching high and ultra-high fresh-meat pet food production technology for years. In 2019, we succussed launched the dry pet food line with up to 70% fresh meat on the market. Since then, our experts have worked on improvement to meet the higher addition demand – and 2021 marks the breakthrough of our solution with several 90%-meat pet food processing lines starting operations in China, Southeast Asia, the Middle East, and South America.

FAMSUN develops specialized equipment such as FE series single-screw extruder, R series twin-screw extruder, CYPZ vacuum coater, etc. for pet food production. These machines are flexible to meet different customized pet food formulas, and the base materials of all product-contact surfaces or parts are food level. FAMSUN CYPZ vacuum coater, especially, allows producers to differentiate their products at the line end through applying different functional liquids onto the food pellets, be it oil/fat to improve energy, flavors to improve palatability, or functional improvers to achieve health.

By introducing FAMSUN innovative and exclusive technologies such as quick-start, waste-controlled preconditioner, intelligent dryer, clean energy machines, and digital services of Manufacture Operation Management (MOM), Manufacture Executive System (MES) and traceability system, as well as advanced Lean Manufacturing and Pull Production concepts, FAMSUN modern industrial pet food solutions provide producers the most possible ways accessing to efficient, responsible, and excellent operations.

At FAMSUN, food quality and safety are the two most essential elements in its solutions. From raw material receiving and fresh meat liquid preparation to product packaging and delivery, every process, equipment, and part of its machines and systems are specially designed to meet the two criteria. We also provide tailored cleaning and disinfection guidelines for every plant to drive biosecurity practices in the pet food industry.

Integration: Turning complex into simple

As an integrated solution provider and a technology partner in the farm-food industrial chain, FAMSUN offers a package of technologies and services from consultation, design, civil construction, manufacture to logistics, installation & commissioning, training, and service to its customers. With end-to-end systematic consideration, design, and execution, producers only have to learn how to operate and manage an advanced modern plant to its best performance and explore its capability to develop and produce competitive products. In addition, FAMSUN's digital and intelligent services and collaborative innovation help drive simplicity and excellence in the whole plant's operation and management.

So far, FAMSUN has delivered more than one million annual production capacity to over 150 pet food producers, including Gambol Pet Group, PureNatural in China, Maxipet in Portugal, AVI-Products in South Africa, BioAlimentar in Ecuador, etc. These producers manufacture over 500 pet food brands to help millions of pets live longer, healthier, and happier lives with their owners.

Together, we can nourish, spark and protect what's good in pets and create pieces of simple happiness in life at scale.

By Famsun

Source: All Pet Food

Manufacturing Process

Manufacturing Process

3+ MIN

22/03/2022

FISO 24378:2022 Feed Machinery Published

March 1, 2022 This document was prepared by the Technical Committee ISO/TC 293, Feed machinery, developed by ISO/TC 293/WG1 (terminology), in which more than 40 members from China, USA, Germany, Switzerland, Iran, Pakistan, the Republic of Korea, Canada, etc. worked together for nearly six years. The project leader and workgroup convenor was Weiguo Wang, professor of Henan University of Technology, China. The Feed machinery terminology standard harmonizes terminology used by manufacturers globally and will supply the basic terms for developing other feed machinery standards and the global feed industry users. Professor Weiguo Wang speaking on the Third Plenary Meeting of ISO/TC293 on 20th Oct. 2021. About ISO/TC 293 Standards are the international language of business. The International Organization for Standardization (ISO) develops and publishes international standards with global expert input. The feed industry, as an important part of the food chain and responsible for producing safe, high-quality animal feed to support safe, animal-derived foods, also needs a common language to facilitate international trade and help ensure the manufacture and delivery of safe, reliable products. Initiated by industry experts in China, the Technical Committee ISO/TC 293, Feed Machinery, therefore, was established in 2014. The scope of this committee includes standardization of single feed machines, processing systems and complete production lines. The participating (voting) members of the Technical Committee ISO/TC 293, Feed Machinery represent 14 countries: Canada, China, Denmark, France, Germany, Iran, Republic of Korea, Pakistan, Romania, Spain, Switzerland, Turkey, the United Kingdom and the United States. Observing members represent 14 countries: Argentina, the Czech Republic, Finland, Hungary, Indonesia, Italy, Japan, Mali, Malta, Peru, Poland, Saudi Arabia, Sweden and Uzbekistan. The ISO/TC 293 currently is administered by the China National Technical Committee on Feed machinery and is developing standards in the areas of terminology, safety and the hygiene of feed machinery. New standards proposed The Technical Committee ISO/TC 293, Feed Machinery held its third plenary meeting of ISO/TC293 on 20-21 Oct. 2021 to discussed critical issues to enhance the feed machinery and feed manufacturing industries. The hybrid event, with the in-person meeting at FAMSUN Group, Yangzhou, China, was officially opened by Professor Fengcheng Wang, ISO/TC 293 Chairman. He welcomed over 30 delegates from the participating countries of China, Canada, Germany, Iran, Pakistan, Switzerland, Turkey, and the United States, and its two connection organizations: ISO/TC34/SC10 Animal Feed Technical Committee and ISO/TC34/SC17 Food Safety Management System Technical Committee. Professor Wang reviewed the work and the progress of ISO/TC 293 since the second plenary meeting, thanked the workgroups for their collaboration and contributions during the pandemic. Delegates discussed the proposed topic and scope of the international standard project of "Safety requirements for feed machinery", the work plan of the international standard project of "Cross-contamination control of feed production lines", and the 'Recommendations on drafting international standards of dust-explosion-proof for feed processing systems' that proposed by delegates from FAMSUN Group. 'We will encourage the world's most outstanding experts – as many of them as possible – to join us in the ISO/TC 293 and offer their opinions on behalf of their country's industry in the coming years,' said Pengfei Zhang, Chief of the Chinese delegation and Vice President of FAMSUN R&D Institute. 'The greater the international participation, the stronger the feed machinery standards will be, and the better they will contribute to the global food future,' he said. Source: Famsun Group

Market Information

Market Information

5+ MIN

18/01/2022

FAMSUN President's New Year Message for 2022

Dear colleagues, friends, ladies, and gentlemen, Happy New Year! We have a group of dedicated people who have stayed at their positions, whether in China or overseas, through hardship and overcome obstacles to deliver solutions and help customers improve operations. Also, we have a group of brave pioneers who try to make changes in our products, solutions, and services to create new growth drivers for FAMSUN. They innovate our business model by introducing digital tools and advanced management skills to achieve FAMSUN resilience, agility, and internal efficiency. Throughout the year, our employees live on to 'Customer-centric' and put in their best to shape FAMSUN's future in the agri-food industry. Thanks to the efforts and wisdom of our people and because of the support of our customers, suppliers, partners, and friends from all walks of life, FAMSUN has received much in 2021. Operationally, FAMSUN Group reports a strong result with all financial indicators growing significantly in 2021. All our business units make their breakthrough performance despite the hardy environment. We have launched a group-wide digital transformation this year, which, in return, has improved the internal efficiency of our organization and allows FAMSUN to provide new value in the coming years. By further developing and simplifying our business processes with the FPD 2.0 tool, we have ensured customer orders delivery as expected and created satisfied customers worldwide despite the pandemic. As the impact of the pandemic, consumers demand more locally produced, safe, quality, and nutritious food. To support our customers to improve their production for new growth, we have taken several initiatives to accelerate FAMSUN's globalization and localization and expand our local capability. Over ten webinars supported by FAMSUN's global experts were held successfully in 2021 to focus on the most interested topics for customers in different regions. About 40 local professional engineering and service teams have been partnering with FAMSUN in the agri-food value chain around the world. The 'International Talents' training program has fostered 107 exceptional multinational talents and experts to enrich FAMSUN's local manufacturing, sales, engineering, services, and management teams worldwide. Most notably, our comprehensive strength has won FAMSUN great honors with the '2021 China National Pilot and Demonstration Entity' for promoting the integrated development of next-generation IT and manufacturing technology, the 'Secretariat Unit of Feed Machinery Technical Committee of ISO', and the 'China National Manufacturing Single-Segment Champion Demonstration Enterprise'. FAMSUN is the only company been awarded these honors in the agri-food sector in China. Dear colleagues and friends, FAMSUN's extraordinary progress is not possible without you. On behalf of FAMSUN, I would like to take this occasion to extend my new year greetings and wishes to all hardworking, dedicated FAMSUN people and your supportive families. I also want to express my sincere respect and best wishes to our customers, suppliers, partners, and friends from all walks of life who have been trusting and supporting FAMSUN's growth all the years in different ways. Wish you all a happy, healthy, and prosperous New Year! Looking ahead, 2022 begins with positive developments - the global economy grew, goods trade rebounded, food commodity prices have begun to stabilize - and combined with big issues like the omicron variant, climate change, and increasing food insecurity. We are all clear that the world cannot address these issues without addressing food, while science, technology and innovation are the keys to a better food security system. As a leading global technology company, FAMSUN will continue to adhere to our mission of 'Creating value, realizing dreams, and contributing to the society' and our vision of 'Creating a secured, affordable and sustainable food future and making life better for all' and take 'Customer-centric' as our behavior principles to achieve high-quality growth through innovation, transformation, investing in people, and making development greener and more sustainable in 2022 with following underlines: First, building a full aspect supporting system to accelerate FAMSUN's globalization and localization. So, we will further localize worldwide with the strong support of group-wide, global-rich resource and investment plans in all operational aspects to ensure more customers in different parts of the world benefit from FAMSUN's leading, whole supply chain, integrated solutions in the coming years. Second, transforming our sales and service model to create new values for our customers with a more cohesive ecosystem that allows for more partnerships, connections, interactions, collaborations, and trust. Third, as a technology supplier, FAMSUN will continue to fuel high-quality development with science, technology, and innovation by increasing our R&D budget and driving the necessary transformation such as digitalization and sustainability. Fourth, to build up a streamlined organization, in which productivity elements are well organized into standard operation processes scientifically and optimally to improve the quality of our products, projects, and services and enhance FAMSUN's local and global order delivery capability and efficiency as well. Fifth, to foster a corporate culture that leads to satisfied customers with happy employees. We will continue to embed diversity, equity, and inclusion in our culture and make every employee feel appreciated, valued, and respected by FAMSUN, regardless of gender, race, religion, color, nationality, educational background, family, and hobby. We believe happy employees can create a sense of belonging and engagement in the organization, which will drive them to go the extra mile to serve our customers and create a better customer experience. By knowing the real demands of customers, they can better contribute to the growth, transformation, and sustainable development of our customers' businesses. Dear colleagues and friends, We have been working to facilitate global food supply, improve productivity, and create new values by providing advanced, responsible, and sustainable agri-food production systems to the world. Every piece of your efforts will contribute to better production, better nutrition, a better environment, and a better life for all. Let's seize the day and live it to the fullest and continue to deliver with even more extraordinary efforts in 2022, leading to an increasingly sustainable, secure, and progressive food system for the world. Thank you! by: Richard Fan - Chairman & President - FAMSUN Group All Pet Food

Extrusion

Extrusion

1+ MIN

13/01/2022

FAMSUN is an integrated solution provider of plants, equipment and services in the farm-to-table industry chain.

It is the food standard factory invested by Tekirdag Un company in Turkey (Europe side), which is fully designed and constructed according to UN food standard. This project use FAMSUN latest twin screw Extruder, steam type Dryer and Paddle mixing system, and pneumatic transporting which are all designed by FAMSUN USA R&D Institute. The success of this project will surely enable Tekirdag Un to offer higher quality, green and safe food to the world. by All Pet Food

Extrusion

Extrusion

1+ MIN

19/11/2021

AVI-PRODUCTS- Second largest Pet Food manufacturer in South Africa

A production line with annual capacity 80,000MT was built up by FAMSUN in 2020, currently, AVI is the second largest pet food manufacturer in South Africa. Over the last decades through innovation and efficiency, pet food has proven to be an essential part of the solution to make the pet food production chain more sustainable. FAMSUN is always working with pet food industries players to meet the sustainability challenge – produce more, using less, at an affordable cost. by All Pet Food