Highlights Q1 2021:

- Order intake 231m€; up 44%; a record high.

- Sales 147m€; up 13%.

- Adjusted EBITDA 17.2m€; up 34% with improved EBITDA-margin of 11.7% (Q1 2020: 9.9%).

- Baker Perkins, the Group's recent acquisition, outperforming expectations.

Order intake (fx-adjusted) grew across several end markets and regions, most notably food (123%), chemicals & performance materials (83%) and the Americas region (83%). Over 50% of order intake continues to be generated from the Group's strategic focus markets of food and mining. Looking forward, across all markets and regions, there is a strong project pipeline reflecting the broad-based pick up in business activity.

In Q1 2021 Schenck Process booked additional orders from a leading pet food producer with current expectations of a total order value of over US$150m by year end. The Group also secured further project wins in the chemicals and performance materials markets. In the Chinese polycarbonate industry, Schenck Process achieved a considerable milestone with a first large-scale order from a leading supplier of innovative chemical products.

With a focus on environmental-friendly solutions, the Group supported customers in achieving their sustainability goals. In EMEA, Schenck Process enabled a cement and building materials producer to reduce the fuel supply from coal and CO2 footprint by introducing alternative energy sources.

In March, Schenck Process launched its digital brand Schenck Process NEXT and introduced its IoT backbone CONiQ® Cloud. Both are key drivers to enhance the Group's digital offerings and leading towards a future of increased connectivity. Further details and updates are available on the Schenck Process NEXT website.

CEO Keith Cochrane commented:

'Despite the challenges of the pandemic, the Group has made a strong start to 2021 delivering a good Q1 financial performance and effective execution on our strategy. I am confident that we can continue to demonstrate the strength of our business model and deliver on our strategy moving forward.'

About Schenck Process

Marketplace

Schenck Process is a leading global provider of sustainable products, integrated solutions and services in mission critical applications for bulk materials. Headquartered in Darmstadt, Germany the Group has 2,800 employees with a presence in over 20 countries across five continents focused on the food, mining, chemicals and performance materials, and infrastructure and energy market segments.

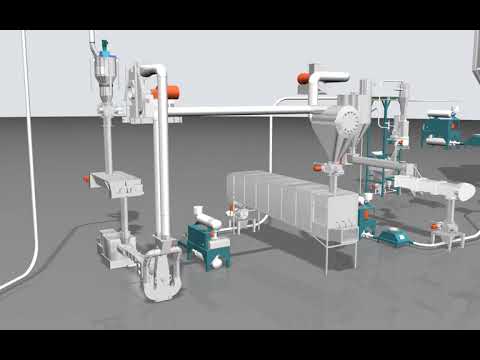

The product offering includes solution for industrial weighing, feeding, conveying, pulverizing and classification, screening, mixing and blending and associated digital applications.

The Group was acquired by Blackstone International in 2017 and generated revenues of nearly €600m for the year ended 31 December 2020.

For further company news and information, please visit

By: Schenck Process

You could be interested: Flagship event for the pet supplies industry: world-leading fair Interzoo 2024 sold out

About company

About company

We Simplify Difficult Pet Food Manufacturing Processes

Producing the highest quality product is at the top of your mind. Your system must minimize product degradation, eliminate inefficiencies, and ensure product safety. Because your process is unique, customized system upgrades are preferable to a one-size-fits-all solution. One thing is for sure, the upgrade must deliver significant cost and energy savings. This could be a tough project. Or maybe not….

Schenck Process provides pneumatic conveying, mixing, blending, milling, sifting, weighing, feeding, dust collection and process control solutions for the world’s most recognizable pet food brands. Protecting your brand? We’ll help you do it. Difficult projects? We’ve conquered them.

Our team of in-house engineers understands the specialized needs of the pet food industry. We’ll help you select the right technology solution and manage your project to a successful conclusion.

Schenck Process delivers custom-designed and engineered solutions for the pet food industry. Here is a sample of some our pet food applications:

- Truck or Railcar unloading & bulk storage systems

- In-plant transfer systems for major, minor and micro ingredients

- Plant controls system upgrades

- Plant dust control systems

- Hammermill aspiration, convey and dust control

- Scaling systems for blenders and extruders

- Continuous dense phase transfer of finished products

- Emissions control systems for dryers and coolers

- Off spec product reclaim and remill systems

- Extruder negative airlifts

- Feeding ingredients into dry kibble and wet shred processes

- Ratioing palatants and dry kibble into enrobers for coating applications

- Measuring mass flow of base ingredients into extruders

- Removal of fines and other extraneous materials

- Gentle grinding of raw ingredients

Marketplace

Noticias de la empresa

5.0

5.0

09/06/2021