Germany — Schenck Process on Oct. 7 added ProFlex C 100 to its ProFlex C portfolio of feeders. Already available in C 500, C 3000 and C 6000, the new C 100 offers small feed rates for a variety of applications in food production.

Schenck Process ProFlex C100 feederSchenck's ProFlex C 100 continuous feeder offers flexibility with quick and clean changeovers. The system is designed to prevent bridging and plugging of sticky powders. The C 100 fits on small extruders and is available in low weight, allowing processors to group up to five feeders around a small extruder or lab inlet.

The ProFlex C 100 has flexible hopper walls and installation option. It is applicable for compound and masterbatch industries.

Each system in the company's ProFlex C portfolio has an asymmetric design, features easy change of discharge, an 8-point massage system, easy dismantling and cleaning, steep hopper walls and is LIW-critical cabling encapsulated

by Schenck Process

You could be interested: Countdown to Pet Food Conveyor Launch: Starting Up On Time and With Confidence

About company

About company

We Simplify Difficult Pet Food Manufacturing Processes

Producing the highest quality product is at the top of your mind. Your system must minimize product degradation, eliminate inefficiencies, and ensure product safety. Because your process is unique, customized system upgrades are preferable to a one-size-fits-all solution. One thing is for sure, the upgrade must deliver significant cost and energy savings. This could be a tough project. Or maybe not….

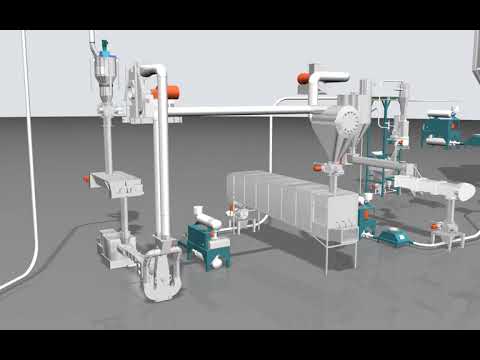

Schenck Process provides pneumatic conveying, mixing, blending, milling, sifting, weighing, feeding, dust collection and process control solutions for the world’s most recognizable pet food brands. Protecting your brand? We’ll help you do it. Difficult projects? We’ve conquered them.

Our team of in-house engineers understands the specialized needs of the pet food industry. We’ll help you select the right technology solution and manage your project to a successful conclusion.

Schenck Process delivers custom-designed and engineered solutions for the pet food industry. Here is a sample of some our pet food applications:

- Truck or Railcar unloading & bulk storage systems

- In-plant transfer systems for major, minor and micro ingredients

- Plant controls system upgrades

- Plant dust control systems

- Hammermill aspiration, convey and dust control

- Scaling systems for blenders and extruders

- Continuous dense phase transfer of finished products

- Emissions control systems for dryers and coolers

- Off spec product reclaim and remill systems

- Extruder negative airlifts

- Feeding ingredients into dry kibble and wet shred processes

- Ratioing palatants and dry kibble into enrobers for coating applications

- Measuring mass flow of base ingredients into extruders

- Removal of fines and other extraneous materials

- Gentle grinding of raw ingredients

Marketplace

Noticias de la empresa

5.0

5.0

05/07/2021

Schenck Process with strong start into 2021: Record high in order intake and launch of digital brand

5.0

5.0

09/06/2021