Innovative design, which has been implemented on virtually every model of KEK® Centrifugal Sifters, features an easy-to-remove hygienic screen basket and paddle screw assembly, a hinged oversize end door, and bolted flanges for dust-tight operation. The sifters also operate quietly without vibration.

The cantilevered design improves efficiency with its clean, simple features that are operator friendly – no tools are required for stripping down and cleaning – along with the time saved during an inspection, cleaning, and maintenance. The units also contain easily removable sifter screens for inspection and cleaning, and easy access via the oversize end door, which opens in seconds. There is zero leakage or contamination from the oversize end door.

The sifters are ideal for feedstock policing, scalping, dedusting, conditioning, and deagglomerating; but can also be used in unique applications, such as de-packing, fruit dumping, inline sieving, gas purging, and explosion containment.

Pending suitability, these sifters are available with white nylon sifting screens, stainless steel wedge wire, or woven wire screens. They are built to handle the most arduous, heavy-duty applications where access for maintenance is severely limited, such as toxic and radioactive processes. Also, optional screen protectors eject incoming extraneous objects, which could damage the sieving mesh. For further improvement of the sifter's hygienic capabilities, the units can also include clean-in-place spray facilities, inlet section access door, and additional inspection doors on the sifter body.

The design is also available on KEK® models K300C, K650C, K800C, and K1150C (the largest cantilevered sifter with capacities of up to 80 tons per hour).

"Schenck Process has established itself as the bulk materials, handling providers trust most throughout the process industries by creating a culture of constant innovation, and always looking at how our extensive product portfolio can better serve customers", said Karin Galloway, Executive Director of Sales – Kemutec North America. "The Kemutec KEK® Centrifugal Sifter line with unparalleled hygienic and ease-of-use standards exemplify that commitment."

To view KEK Centrifugal Sifters in action, click HERE

Source: Schenck Process

You could be interested: Waste to Energy Plant uses Scalebreak-Mp on Dump Condenses - Get Sparkling Clean Results

About company

About company

We Simplify Difficult Pet Food Manufacturing Processes

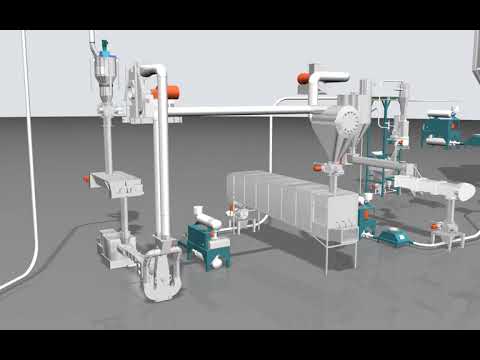

Producing the highest quality product is at the top of your mind. Your system must minimize product degradation, eliminate inefficiencies, and ensure product safety. Because your process is unique, customized system upgrades are preferable to a one-size-fits-all solution. One thing is for sure, the upgrade must deliver significant cost and energy savings. This could be a tough project. Or maybe not….

Schenck Process provides pneumatic conveying, mixing, blending, milling, sifting, weighing, feeding, dust collection and process control solutions for the world’s most recognizable pet food brands. Protecting your brand? We’ll help you do it. Difficult projects? We’ve conquered them.

Our team of in-house engineers understands the specialized needs of the pet food industry. We’ll help you select the right technology solution and manage your project to a successful conclusion.

Schenck Process delivers custom-designed and engineered solutions for the pet food industry. Here is a sample of some our pet food applications:

- Truck or Railcar unloading & bulk storage systems

- In-plant transfer systems for major, minor and micro ingredients

- Plant controls system upgrades

- Plant dust control systems

- Hammermill aspiration, convey and dust control

- Scaling systems for blenders and extruders

- Continuous dense phase transfer of finished products

- Emissions control systems for dryers and coolers

- Off spec product reclaim and remill systems

- Extruder negative airlifts

- Feeding ingredients into dry kibble and wet shred processes

- Ratioing palatants and dry kibble into enrobers for coating applications

- Measuring mass flow of base ingredients into extruders

- Removal of fines and other extraneous materials

- Gentle grinding of raw ingredients

Marketplace

Noticias de la empresa

5.0

5.0

09/06/2021