PLP Systems

https://www.plp-systems.com/PLP Systems

About company

INFORMATION

P.L.P. Systems, founded in 1980, is a business reality specialized in dosing and weighing of liquids and powders for production plants of pet food, feed, food for human consumption and chemical products.

P.L.P Systems can supply complete systems for liquid and powder dosing control, continuous coating on finished products, microdosing, emulsifiers, motorized sprayers, flow meters, pumps, filters.

In the pet food sector, PLP SYSTEMS has developed precise and reliable technological systems. It is one of the companies with the highest internationally recognized technological added value.

PLP ON LINE EXHIBITION

Due to Covid's situation that it has canceled the various exhibitions where we were going to present our latest technology, we plan to keep in touch with our customers in a different way, therefore we are pleased to announce our 2020 online exhibition.

Please check the latest products in

We are available for any future information. Let's keep in touch!

Products

Company News

Market Information

Market Information

2+ MIN

09/11/2023

PLP Systems: When quality meets experience

The company focuses on developing customized systems talored to clients' specific needs, creating solutions for each project. PLP Systems invests as well heavily in R&D each year, to create new concepts and continuously improve existing technologies. Their dedicated team of engineers and techniciand are experts in dosing, mixing, spraying, coating and handling liquids and micro powder additives. Through R&D, PLP identifies key requirements and potential areas for innovation, they then design, test and optimize new solutions to meet demands for higher productivity, quality and sustainable processing. With a commitment to quality, PLP Systems builds all equipment to the highest standards. Each system is meticulously engineered and constructed from high-grade components to ensure maximum efficiency, reliability and a long operating life. Stringent quality control procedures and testing guarantee consistent performance and safety of all machines before shipping. After installation, PLP Systems provides full after-sales support and service to assist customers in getting the most from their investment. By establishing open and enduring customer relationships built on trust and understanding, PLP is able to support the long term success of their clients. Recently the company has increades its participation in fairs both in Italy and around the world, expanding its know-how, expertise and technologies to an even wider and more diversified audience. PLP Systems is convinced that through direct and human contact, lasting and solid relationships can be established. By continuously enhancing their knowledge and skills, PLP Systems will continue provide innovative and high-quality solutions to meet the changing needs of the pet food and feed industries. About PLP Systems By: PLP Systems

Coating

Coating

2+ MIN

20/06/2023

MASS SPIN COATER - Revolutionary patented system

The pet has become a true member of the family and the end customer, his owner, is increasingly oriented towards high-quality food in terms of well-being, quality and pleasure. PLP takes up this challenge by developing systems that can translate market needs into real products. The treatment and coating system, patented as MASS SPIN COATER, is the new and revolutionary system for coating and adding additives onto solid products. Through an integrated torsion transducer and a processor of Coriolis force data, the MSC is capable of identifying the mass delivery rate of solid prodcts (pelets, flours , croquettes). This permits a proportional control for adding doses of additives for the process. The MSC guarantees the uniformity of the finish products and thanks to reduced dimensions and weight, installation is made easy at any point of the system, be it on the transport piping in the drop, or at the end of production directly onto the vehicle load. It is used for applying either powder or liquid additives: - Fat : for adding vegetable oils or fat in general. For adding molasses and other products largely used on the finished products - Enzymes : for adding liquid enzymes and powder enzymes directly onto the finished product, to avoid cross contamination between the various products and to avoid waste due to degradation of the enzymes during the production of feed. - Powder condensation : Fine powders, in an environment saturated with the same, cause serious problems such as explosions and subsequent fires , as well as serious respiratory problems for personnel and, last but not least, damage to the plant. which remain in the production cycle without creating further problems - Humidification: For the treatment of humidification in raw materials with the addition of water and acidifiers with retroactive checks of humidity present in cereals - Treatment after pelletizing : The addition of medicines in the production of feed is normally carried out in the mixing pase with contamination problems and loss of active ingredients due to mechanical and thermal stresses. With the MSC it is possible to add antibiotics, coccidiostats, vitamins etc, whether in liquid or powder form. This process is possible thanks of the utilization of Seal4feed , a filming product from ARDA Innovations product of ARDA INNOVATIONS. by PLP System Source: All Pet Food

Coating

Coating

2+ MIN

24/11/2022

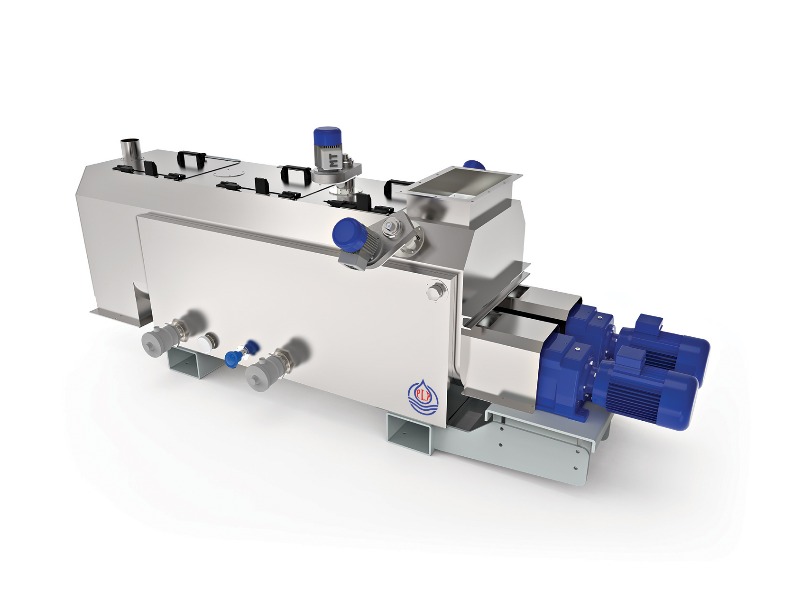

Continuous Coating: High retention time

The coating of pet food croquettes is an important phase of the process, as the external covering of a croquette is the initial contact with the animal as well as the main point of reference that the customer will trust. The coating phase must be carried out to: Obtain color homogeneity in all croquettes Reduce oil loss and greasy look and feel Improve the distribution and homogeneity of palatant and flavoring additives. Reduce disinfection problems in the coating process CONTINUOUS COATING BENEFITS Pro: High-level of homogeneity (CV) can be obtained even with the addition of low amounts, being more flexible and kind with the production and the product itself. Requirements for a successful application: Performing croquettes dosing: The dosage must be carried out using continuous gravimetric weighing systems, not volumetric. The variation of the incoming product flow must be adjusted and stabilized by the proportioner to have a uniform output. Covering: The team must be as gentle as possible with the product but should also guarantee good mixing homogeneity. The retention time is essential when high amounts of oils are added, and should not be less than 60 seconds. Atomization: Continuous atomization is a real challenge, especially when the product flow varies. Standard nozzles are always exposed to dirt and blockages. PLP recommends SMOG Technology for perfect atomization in any condition and viscosity. *Typical diagram of a continuous coating installation In addition to the points mentioned above, there is another very important factor during the coating process, which will result in a more homogeneous final product: HOLDING TIME Homogeneity is also related to the absorption of fat by croquettes. As for the process, this can be increased thanks to the combination of heat and croquette retention in the mixing phase in the covering. The MT series is equipped with heating chambers that maintain a controlled temperature inside the machine, while the retention time is increased by: Adjustment of the angles of the vanes Adjustment of the speed of the rotary axes Internal shock absorbers RETENTION GATE PLP has developed an automatic check gate, located at the outlet of the machine. It is suitable for stopping the croquette flow and releasing it when product accumulation reaches a certain level inside the machine. Thus, it significantly increases the retention time, up to 180 seconds inside the MT machine. For more information visit the PLP Systems WEB or contact this EMAIL. Source: PLP Systems

Dosing

Dosing

2+ MIN

30/08/2021

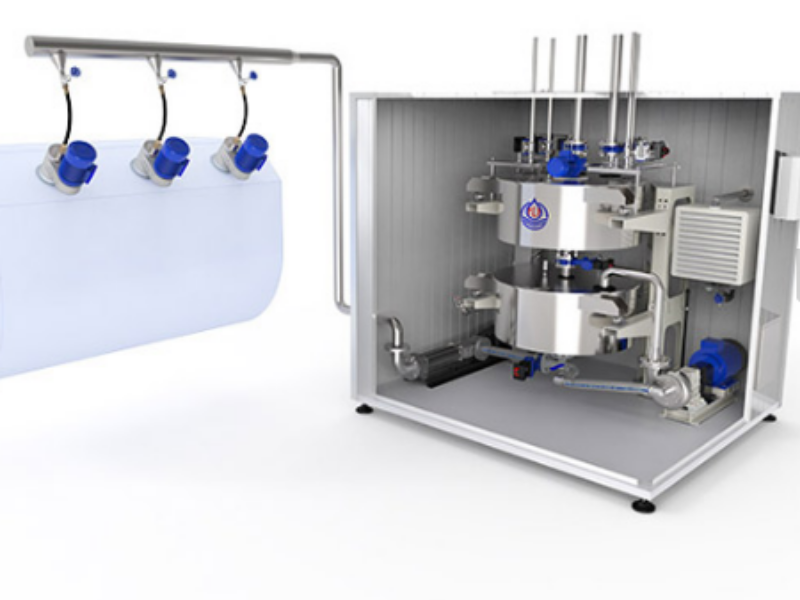

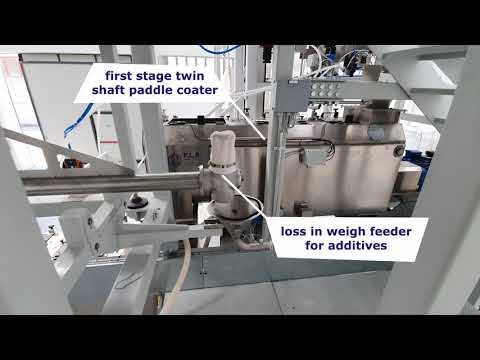

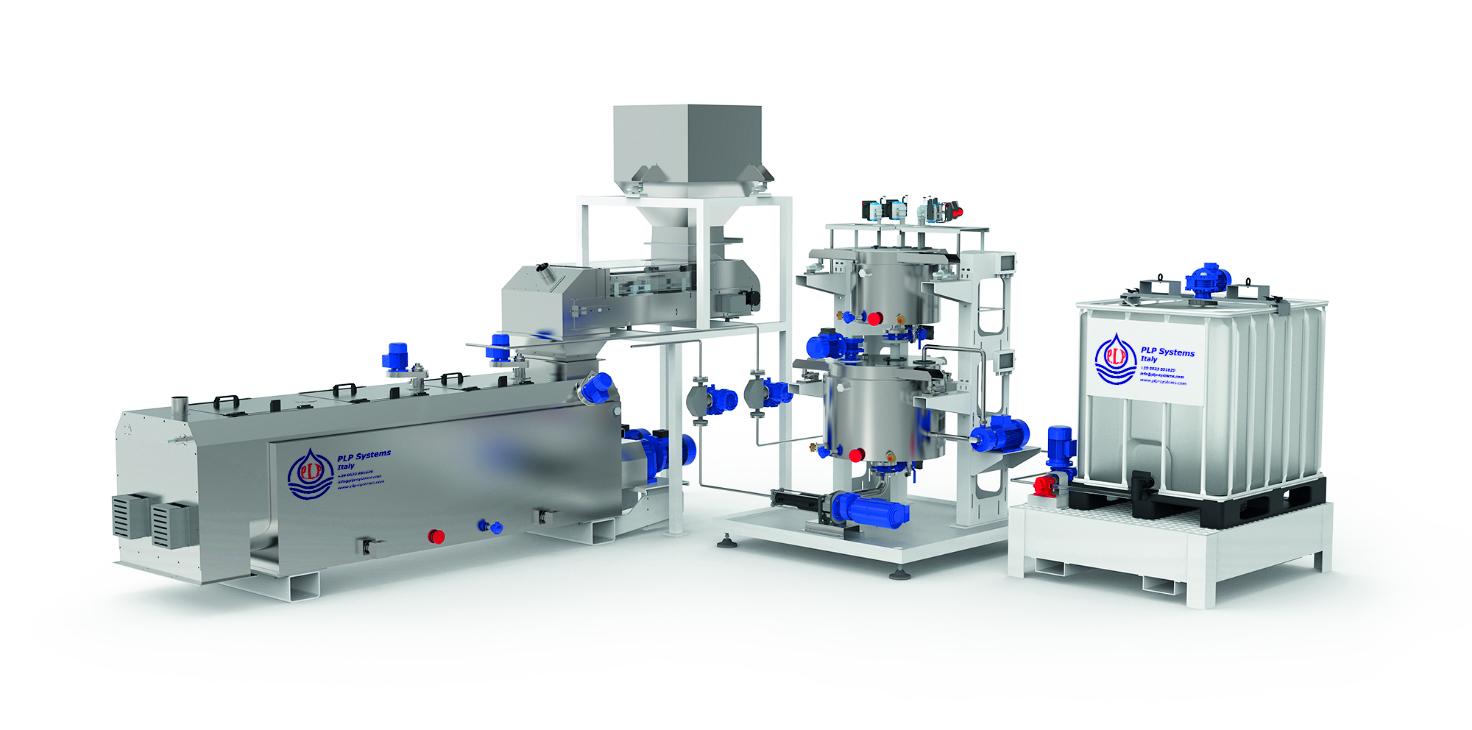

PLP Systems pilot plant for continuous coating

There was a key change once a continuous coating test plant was developed in our company that can reproduce the full capacity of the industry demands, to minimize the difference in results between a laboratory test compared to actual production. This internal continuous coating test plant is used for: Technological innovation of PLP and know-how to compete in the market with the application of pellet coating. Customers looking for creative applications are available to perform testing and developing new products for your pet food by coating them with powders or flakes such as spices, vegetables, cheese, flavors, nutritional agents, etc. Too to coat semi-moist or baked pet food. Customers who want to test PLP technology before purchasing the system can perform the test of the complete coating line. The pilot plant can be adapted for different products with a production capacity from 300 kg / h to 15 ton / h, managing different densities. It is equipped with a precise gravimetric continuous dosing of the main product (croquettes) carried out by means of a weighing tape or a weighing thread. Dosing of liquids by pump and flow meter and dosing of powders by weight loss feeders. All controlled by the automation and proportional dosing adjusted by frequency control drives. The test plant can be integrated with 3 different PLP coating technologies: DRUM ROTARY; COVER WITH DOUBLE AXLE BLADES; MASS SPIN COATER. ROTARY DRUM The latest development over the more traditional rotary drum, this machine is specially recommended for semi-wet products, small extruded or granulated pellets and lower production capacity. The special corrugated shape of the drum increases the rotation of the product, at the same time protects it from damage and reduces waste inside the machine, making it a perfect machine to be used in food application or with special kibbles for pet food. CONTINUOUS COVER WITH DOUBLE AXLE PADDLES It is our most widely used machine for standard pet food production and has received the majority of R&D improvements during the last years. There are different models that can cover all required production ranges with high liquid inclusion rates or fats. The focus of the machine is the retention time and this is achieved by regulations of speed independent of the axles, internal dampers and automatic check valve in the output of the product. The retention time in standard pet food production it can reach up to 200 seconds. MASS SPIN COATER Compact continuous cover used to add micro liquids up to 1%. The MSC integrates a continuous precision weighing technology, based on Coriolis forces. Thanks to a nozzle special is able to obtain a perfect homogeneity even when the inclusion rates are less than 0.1%. Source: PLP Systems

Preservatives

Preservatives

2+ MIN

10/07/2020

PLP Systems launch Innovative Online Exhibition Stand

Italian dosing and handling specialists, PLP Systems, have recently launched their online exhibition stands, showcasing their latest, innovative solutions for a digital audience. With the continued postponement of trade shows due to COVID-19, many companies have taken to online exhibitions in order to provide customers and industry leaders with an opportunity to better understand their solutions, and PLP Systems have launched a state-of-the-art platform that truly showcases their expert solutions to the market. PLP Systems was founded in 1980, by three friends passionate about the farming sector they grew up in. Through their technological studies, they came to form PLP Systems and innovate the future of liquid and powder dosing systems for a variety of industries. The polished online exhibition and wide variety of solutions on display demonstrate that the company continue to grow and are leading members in the liquid and powder handling sector. The online exhibition stand is categorised into three sections; pet food, feed and aqua feed as well as food equipment. Attendees can explore these sections in detail at a virtual booth and explore the various solutions PLP offer for a variety of processes, ranging from micro-dosing, process hygiene, liquid spraying and pellet coating. One of the most intriguing aspects of their presentation is their new nano-dosing system for animal feeds. PLP's nano-dosing solution, the Nano-DP is designed for dosing very small batches of feed with extreme precision. These products are then forwarded onto the main batch mixer. This solution is ideal for dosing antibiotics and other medicinal materials for feed, as well as low inclusion additives. Should attendees have any questions concerning any of the solutions on offer, contact forms are readily available for them to get in touch with a member of PLP System's expert team. You can access the online exhibition at: mymag.info/e/879 By PLP Systems Source : Milling and Grain