Gea Group

https://www.gea.com/es/company/index.jsp

Gea Group

About company

About us

GEA is one of the largest technology suppliers for food processing and a wide range of other industries. The global group focuses on technologies, components and sustainable solutions for sophisticated production processes in diverse end-user markets. Our customers are at the heart of everything we do and we build strong partnerships with them. We provide individual and sustainable solutions for a wide range of customer-specific industries.

Founded in 1881, GEA has continued to develop and set new standards to meet the needs of the market and its customers. Today, GEA is a globally active and leading company, known for its outstanding technologies worldwide, particularly for the food industry.

We strive to be the world’s leading technology group, providing innovative and sustainable solutions for sophisticated process industries.

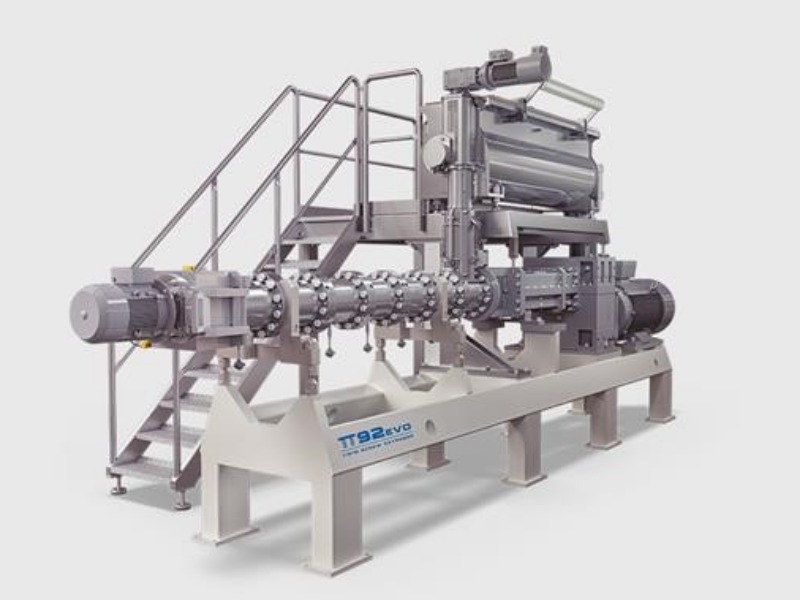

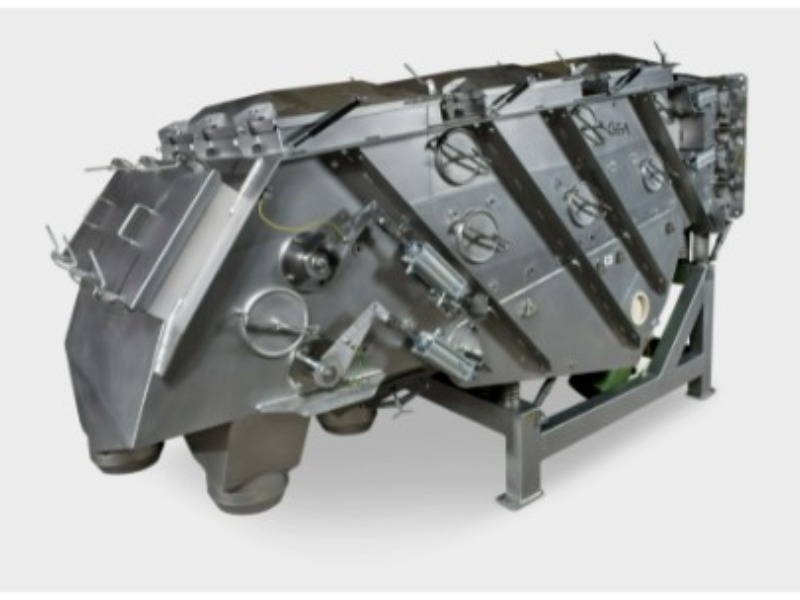

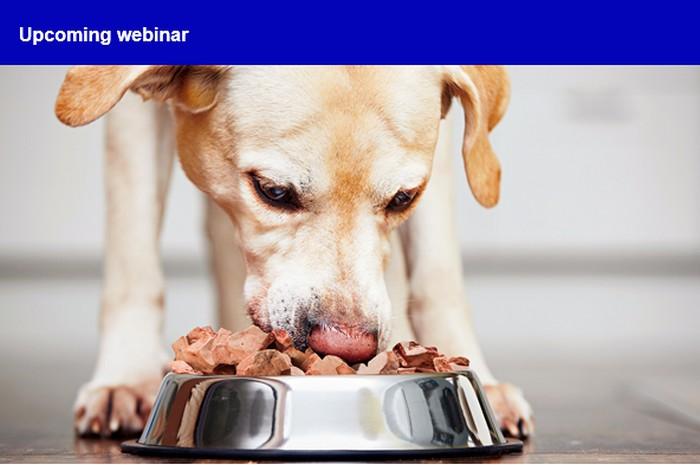

Dry Pet Food

On a market where customers increasingly demand products as similar as possible to the ones for humans from a nutritional and production quality point of view and for the variety of formats, our many years of experience in developing food processing technologies allow us to offer futuristic solutions able to set new standards on the market.

Our philosophy leads us to work alongside our customers, supporting them in creating and developing innovative products, helping them define the formulations, forms, consistencies, weights, flavors and colors that best satisfy the demands of the final consumer. We share their goal of obtaining an innovative and high-quality industrial production based on collaboration that starts with research and is embodied in the provision of the most advanced processing technologies.

Applications: kibbles, pillows, dental sticks.

R&D and pilot plant

We feed our success through constant and thoroughly organized Research & Development activities performed by a team of 30 people that includes process technicians, analysts and mechanics. They have at their disposal 2000 sq. m of facilities equipped with a completely new pilot plant capable of developing new products in all respects and a laboratory equipped with all types of instruments for chemical, chemical-physical and rheological analysis and nutritional/organoleptic testing.