Ferraz Máquinas e Engenharia Ltda.

http://www.ferrazmaquinas.com.br/

Ferraz Máquinas e Engenharia Ltda.

About company

FERRAZ is the Brazilian market leader in the production of equipment for the animal nutrition industry and exports its products to other countries. Based in the city of Ribeirão Preto, São Paulo – Brazil, today occupies an area of 70,000m² in its plant, the company designs, manufactures, assembles and installs complete lines of equipment for the production of animal feed type: Bran Feed, Extruded and Pelleted. Since the beginning of the project to the operation of the plant, Ferraz has specialized professionals to provide services such as automation, start up in the field, assembly, employee training, technical support, spare parts; Supplying all the needs of a feed mills.

Products

Company News

Market Information

Market Information

3+ MIN

09/03/2023

Ferraz: from Brazil to the world

Over the years, we have greatly expanded our products and services portfolio until reaching the current stage, in which we supply complete plants for the production of 400 kg extruded meal feed at 16 tons per hour, 400kg pelletized at 30 tons per hour, and plants for mineral salt and premix production. Nowadays, we are leaders in the market for machinery for extruded food production in Latin America. In addition to the equipment, we also supply spare parts, through the division called "Ferraz Parts", such as dies and roller covers for all the main pellet brands of the market. Our arrays, made of stainless steel material with perforation technology using gun drills and a vacuum quenching process, are what ensure an excellent roughness profile for the holes. We also provide services such as Munck leasing, freight through our own fleet, and installation of compressed air, steam, liquids, and electrical networks. The 'Autofer' division, our subsidiary dedicated to electricity and automation, has a large and qualified team for the supply of power and control panels, CCM, and industrial automation software. One of the great company's competitive advantages is its capability to supply from the receiving hopper to the bagging machine, that is, all the necessary equipment for the feed production process. In addition, we have the premise of dedicating special attention to after-sales, for which we maintain a high stock of spare parts for immediate delivery, and we also have a team of qualified technicians and specialists in each process, who are always visiting our clients and checking if needs some support, such as maintenance services (preventive and corrective) or training for its operators. We monitor and support clients from the project-design phase, equipment manufacturing, delivery, start-up, and training of contracted operators. Currently, we sell our products and services to 21 countries, with Latin America and the African continent as our principal markets. We consider it of great importance that the company always maintain its original values, which are respect and focus on customer satisfaction, the continuous search for innovation, and the humility to learn and share knowledge with all the people we are in contact with. Significant investments are also made in our team's qualification, either through courses and training given in the company itself or through cost allocations for undergraduate and specialization courses. We always seek to offer the best cost/benefit ratio for our customers, which is why we attach great importance to maintaining short delivery times, as well as competitive prices and strict quality standards. The delivery time for complete factories, for example, is currently 4 to 6 months, depending on the size and complexity of the project. One of the most outstanding pieces of equipment in our current portfolio are the twin-screw extruder and the model for the production of 10 to 12 tons/hour, E-150D, which was recently launched on the market. We have already observed great interest and demand for this equipment, mainly due to its high flexibility and productivity. By: Ferraz Machinery Source: All Pet Food Magazine

Trends

Trends

5+ MIN

19/05/2022

Automation resources for the animal feed production segment

Secondly, an increased level of automation is needed to guarantee stipulated quality standards; and facilitate processes control and data accessibility by industrial managers. This phenomenon of an increased level of automation, real-time process control, and digitization of information is globally known as the "Industry 4.0 ". However, we can´t avoid asking ourselves how this phenomenon applies to animal feed production. What resources do we already have available today? And what advantages can these automation features bring to the productivity and efficiency of industries? Next, we try to describe, in a summarized way, what technologies are currently available for each production process of a feed manufacturing industry. Reception of raw materials It is possible to establish "entry routes" for each raw material received: since the moment the automation software gets the information about what raw material is being received, it can automatically determine the "path" which that raw material must take to arrive at its destination. That is to say, to establish through which equipment the product will pass until it is properly stored. In addition, the reception and dosage silos usually have minimum and maximum level sensors or load cells, so it is possible to know exactly how much merchandise is in each silo, or at least if the said silo is full or empty. This technology is essential to avoid, for example, cross-contamination in the reception process, that is, to prevent the soybean meal that the factory is receiving from going to a silo that already has a different raw material, such as organ meal. Dosage of macro and micro-components Through dosing automation software, it is possible to know exactly how much of each raw material was used in a given production batch and the variation for the quantities previously stipulated. That is to say, we can know how much, more or less, of each product was dosed in each batch. In addition, it is possible to know how much of each product was used in a day, month, or year, which permits automatic inventory controls. Another available resource is the register of the formulas produced. This way, when there is a need to make a product already registered, it is only possible to select the existing one, which must contain all the information in terms of raw materials used, quantities, and location. In addition, it is possible to issue alerts if, for example, there is not enough stock of a specific raw material to comply with the provisions of the registered formulation. Grinding Generally, above the mill, we have a feeding system, which can be done through a dosing thread or, more commonly, a rotary valve. The automation software can increase or decrease the rotation of this feeder valve according to the amperage main mill motor. That is to say, if the equipment is working very close to the maximum amperage of the motor, the automation will make the rotation of the valve automatically decrease, consequently reducing the volume of raw material entering the mill per period. On the contrary, automation will increase the product flow entering the mill if the main motor is working with excessively low amperage. In addition, it is possible to install sensors in the mill to measure temperature and vibration, for example, and parameterize the software so that it turns off the equipment if the maximum allowed vibration limit hits. Extrusion By using load cells in the tank that feeds the extruder's dosing thread, it is possible to know how much flour enters the equipment per period. From these data, and using flowmeters, it is possible to automate process parameters, such as the dosing thread rotation, the cutting system rotation, and the volume of inclusion of water and steam in the preconditioner for each formulation to be extruded. It is also possible to automatically increase or decrease the flour volume entering the preconditioner, based on the amperage of the main engine of the extruder. That is to say, if the amperage measurement shows that the motor is working near the limit, the software automation automatically decreases the rotation of the dosing thread. Similarly, alerts can be issued if, for example, there is a lack of flour in the agitator tank or the steam entering the preconditioner is under pressure. Finally, the measurement in real time of the food density after the extruder is out; thus, the level of water activity of the food after passing through the dryer can also be performed. Pelletizing The main automation features currently existing for the pelletizing process are automatic lubrication systems for rollers, adjustment systems for the distance between the roller cover and the die, and the function of increasing or decreasing the thread rotation. The feeder supplies the pelletizer according to the amperage of the principal motor. These features primarily aim at reducing equipment downtime for process adjustments and maintenance. Coating Taking as example batch coating system of oil, palatants, or molasses, we can install load cells in the lung silo or in the coating itself, in order to know in an accurate way the exact volume of feed to be coated in a specific batch. With this information, and using load cells or flow meters to control the liquids to be added, it is possible to stipulate the exact percentage of each liquid to be dosed and their time and sequence application. That is, which liquid will be applied first and which one later. This happens in addition to registering the formulas used, already with the process parameters of each product. Bagging There is automation software for bagging that automatically performs the self-correction of the weight reached in each bag: based on the stipulated weight and comparing it with the weight reached in the last weighed bags, the software automatically seeks to reduce the variation and get as close as possible to what is stipulated. In addition, there are semi-automatic and automatic bags. Semi-automatic bag lifts dose and weigh the products, but they require the operator to open and place the bag in the bagger. Automatic baggers already have a Cartesian suction cup system or robotic arms that open and position the bags in the correct form, which eliminates the need for human labor in the process. Palletizing There are Cartesian or robotic systems to automate the function of positioning the bags and forming the pallets according to the previously stipulated layout. In addition to providing labor cost savings, these systems can also ensure that the pallets will actually be assembled according to the previously stipulated design, i.e. number of bags per layer, number of layers, correct positioning of each bag, etc. Author: Luiz Gomide Ferraz By: Ferraz Maquinarias

Manufacturing Process

Manufacturing Process

1+ MIN

31/08/2021

Automation technology: a new division arises in Ferraz!

The new division offers complete engineering, updated with the market, where the proposed services are previously studied and reviewed, to always offer the best for the client to obtain productivity, quality and traceability. Through qualified professionals, AutoFer is able to develop services such as panel assembly, creation of supervisors, development of command and control positions, independent automation and industrial connectivity, all within the company itself. Online factory management AutoFer develops software that manages total control of the factory, accelerating access to production data directly through the cell phone; online, in real time, customized to the needs of each client. Source: Ferraz

Extrusion

Extrusion

1+ MIN

25/06/2021

Tips to improve Ferraz Equipment

With this in mind, we are preparing short videos with tips on how to operate equipment, like mills and twin-screw extruders, for example, and help you in this important maintenance and performance process. Subscribe to our YOUTUBE channel where we constantly publish videos with usage guidelines, suggestions and information about Ferraz equipment, in addition to the services and training we offer. See the latest videos published: Source: Ferraz Máquinas e Egenharia LTDA.

Extrusion

Extrusion

1+ MIN

12/02/2021

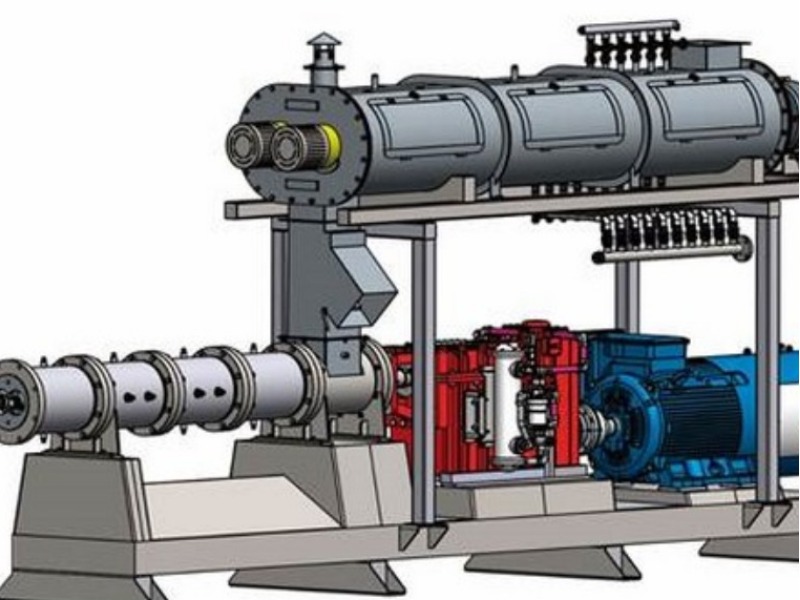

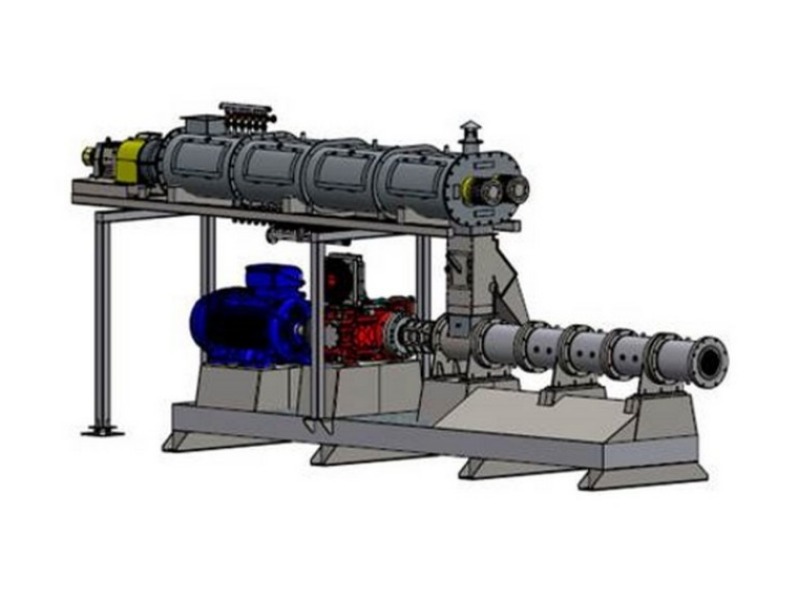

Ferraz launches its news Twin-Screw Extruder: Model E-150D

Before with a line of twin screw extruders with capacities ranging between 400 and 8,000 kg/h, Ferraz now is launching its extruder with the highest production capacity - up to 10,000 kg/h: the Ferraz E-150D. The E-150D twin screw extruder has more advanced technology than single screw extruders, with features such as: Greater flexibility in the configuration of different thread profiles and greater ease in changing and replacing them; greater versatility. .Possibility of working with diets that have higher levels of ether extract, as it offers greater pressure and expansion of the product. Works very well with the addition of fresh meat. Easier cannon cleaning - smooth, non-fluted or helical liners. Variety of products: beef, bi-colored, nuggets, among others. If your focus is on premium, high premium and super premium rations, we have a right twin screw extruder for your production, talk to us! [email protected]