Extru-Tech Inc.

http://www.extru-techinc.com/af

Extru-Tech Inc.

About company

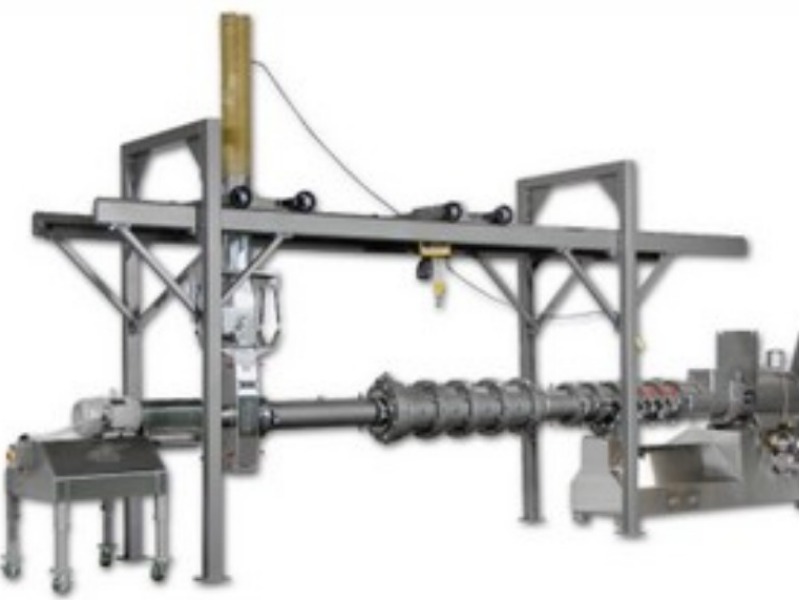

Founded in 1985, Extru-Tech® has installed numerous extrusion systems worldwide designed for the production of human food, pet food, aquatic feed and animal feed products. Extru-Tech® also maintains the reputation of supplying the extrusion industry with superior quality replacement parts.

Extru-Tech® currently produces and markets one of the industry's most complete lines of extrusion processing systems. In addition, they offer a full line of ancillary equipment and customized equipment solutions for specialized processes

Products

Company News

Extrusion

Extrusion

1+ MIN

22/02/2023

The leading Extrusion Seminar in Pet Food and Aquaculture is Back

In conjunction with the Universidad Autónoma de Baja California, Extrutech is ready to offer a in person seminar of high academic value. The seminar will count with theorical and practical activities which will be announced in due course that same day, and are included within the contract. The seminar will be held at the Hotel Coral and Marina, located at Carretera Tijuana-Ensenada Km. 103 N.° 3421, Zona Playitas, 22860 Ensenada, B.C., México, (a few steps from the UABC Pilot Plant). The Hotel offers preferential rates, exclusive for those attending the seminar, prior reservation providing the code: "Extru-Tech Seminar 2023". These RESERVATIONS can be made until Friday, March 17th and are subject to availability. All seminar attendees must be duly registered in advance. Spaces are limited! So, we invite you to contact your Coordinator Isabel Gajardo if interested on attending About Extru- Tech Founded in 1985, Extru-Tech® has installed numerous extrusion systems worldwide designed for the production of human food, pet food, aquatic feed and animal feed products. Extru-Tech® also maintains the reputation of supplying the extrusion industry with superior quality replacement parts. Extru-Tech® currently produces and markets one of the industry's most complete lines of extrusion processing systems. In addition, they offer a full line of ancillary equipment and customized equipment solutions for specialized processes To know more about Extru- Tech we invite you to visit the company´s WEBSITE. Source: All Pet Food

Extrusion

Extrusion

4+ MIN

24/08/2021

Maximum flexibility with a single screw extruder

More than ever, today's consumers view their pets as members of the family. Just as a father or mother wants the best food for their children, pet owners want the same for their pets. The humanization of our pets has been the turning point that has generated the greatest change in how we see and how we relate to these new members of the family. Millennials, without a doubt, are the most influential in all these changes because they are more informed and are much more demanding, especially when choosing food for their pets. They not only hope that the food meets all their nutritional and quality expectations, but also that their pet will enjoy their food a lot. If they observe that their pet does not like the food, not only do they not buy it again, they also share their experience by word of mouth and viralize it through social networks, affecting the manufacturer's sales. Although the Latin American pet food market is generally characterized by a higher level of consumption of affordable and premium foods, the consumption of super premium foods has been gaining strength as a result of consumers being more informed and, therefore, they increasingly demand better quality ingredients and sources of nutrition with greater nutritional contributions, in addition to more sophisticated ingredients. There is no definition of a super premium food, but what is certain is that pet foods that are marketed as super premium use increasingly complex ingredients. On the label it is usually crossed with the selection of raw materials, concepts such as organic, holistic, 100% natural and ketogenic, among others. But, in addition, the offer is expanding to much more sophisticated levels towards extruded foods with high levels of addition of fresh meat, with a very large variety of protein of animal origin such as chicken, salmon, turkey, duck, rabbit, lamb among others; and in the case of vegetables such as berries, apple, carrot, chard, peas, etc. As well as food for certain health conditions of pets such as obesity, sensitive skin, allergies, diabetics, neutered, gastrointestinal, liver, urinary problems, others. In this diversity of products, there are super premium grain-free or grain-free foods, which, despite having no real nutritional reason for having this condition, are produced simply because consumers seek them. Manufacturers often combine this genre with some of the sophisticated raw materials they offer such as those mentioned above. Manufacturing super premium foods, whether with or without grains, can pose significant challenges at the production level. Achieving a nutritionally complete meal requires a greater number of ingredients to obtain the proper balance, particularly with regard to amino acids and essential fatty acids. Extru-Tech has developed state-of-the-art technology to produce high-quality, aseptic foods that meet the nutritional requirements of pets and the high expectations of owners, and has extensive experience working with the largest and most important North American pet food producers. In practice, it is often thought that formulating one type of food or another, reaching all segments and using a wide spectrum of raw materials, has to do only with a formulation issue. But the truth is that the problem is much more complicated than that. The more complex the formula, we find that not all extruders on the market are capable of processing them properly and delivering a food of high nutritional quality, where the croquettes have the texture, hardness and above all the palatability that the owner of the pet expects to find, when it gives the food to its gift. There are two extrusion technologies. One is single screw and the other double screw. Much has been written about the differences between the two technologies and it is true that they do. However, you have to look at both extrusion systems from different angles to know which one is best when deciding on the investment. - When analyzing the differences in the production of food for human consumption, without a doubt, the twin screw extruder has great advantages and greater flexibility over that of a screw. - In the production of pet food and aquaculture food, today there are no significant differences in terms of product quality between Extru-Tech technology with its single screw extruder and those with double screw. What's more, it has great advantages such as: From an investment cost point of view, single screw extruders are cheaper. The cost of production in a single screw extruder is also lower, since it uses a considerably smaller motor, even producing in some cases, greater production capacity with the same product quality. The cost of maintenance and spare parts is also notably lower in single screw extruders. -Variety of products At Extru-Tech we have the technology to produce a wide range of foods in the same single screw extruder, for example: Pet food • Croquettes from 1 to 4 colors and multiple shapes simultaneously. • Bi-colored and marbled foods. • Food from inexpensive to super premium with the addition of high levels of fresh meat • Short and long semi-wet treats or prizes of 1 or 2 colors Aquaculture Feed • Floating, slow and fast sinking • Shrimp foods • Micro pellets from 0.7 mm diameter upwards With Extru-Tech technology and technical support, you will be assured of producing the best quality and most palatable foods in any category, with the lowest production, operation and maintenance costs on the market. Source: Extru- Tech

Market Information

Market Information

2+ MIN

15/04/2021

Jordan Niegsch introduced as Process Implementation Specialist at Extru-Tech

In an effort to continually improve product and process development for its customers, Extru-Tech, Inc., recently announced the addition of Jordan Niegsch as Process Implementation Specialist. A graduate of Pittsburg State University, Mr Niegsch has spent the past 12 years working in the petfood industry, where much of his focus was on single screw extrusion and high-meat-inclusion diets and overall plant operations. According to Scott Krebs, Executive Vice President for Extru-Tech, Mr Niegsch's role will involve all aspects of product and process development and support, including working with the Innovation Group to develop and deploy new technology for its clients; participating in process improvement; training clients to benefit from new technology, and participating in strategic planning and evaluation. "Jordan has already held numerous operational positions during his petfood career, ranging from assisting a start-up company to working for the largest co-manufacturing network in North America,'"adds Mr Krebs, noting that Mr Niegsch has worked with Extru-Tech equipment numerous times along the way. "Consequently, his role with our company will be to work closely with our team in the creation, development, implementation and field support work regarding Innovation Projects. In the process, he will use resources both internal and external to ETI to execute directives. Management has no doubt Jordan will be involved in every segment of our business." "I'm excited to be part of the Extru-Tech team,' Mr Niegsch relates. 'I've worked with this group for many years and tested several pieces of research and development equipment and procedures in my previous facilities; I look forward to being on the other side and helping ETI customers improve their processes and equipment." "This job allows me,' he concludes, 'to help to facilitate a project from the concept stage all the way to the customer, working with all departments of ETI along the way." Visit the Extru-Tech website, HERE. Fuente: Extru - Tech

Extrusion

Extrusion

1+ MIN

12/06/2020

Talking about Extrusion Process in Rongorongo Live with Osvaldo Muñoz

Yesterday morning we had the pleasure of having a friendly chat with Osvaldo Muñoz through Rongorongo Studios in the UK, about one of the hottest topics in aquaculture and pet food processing nowadays ... Extrusion Being one of the most respected voice regarding processing and extrusion process, not only in Latin America but globally, Osvaldo Muñoz, Extru-tech` Sales Director for LATAM , agreed to speak with Roger Gilbert, CEO of Perendale Publishers ltd., Editorial that counts among its publications with International Aquafeed Magazine, among other publications, and with Ivan Marquetti, Regional Director of International Aquafeed and All Extruded magazines and Online Platforms, regarding general aspects of Extrusion and its nutrition and processing benefits for the aquaculture and Pet Food industries. It was a bilingual interview (English and Spanish), so we invite you not to miss any detail of the interview, which touches very innovative aspects of Extru-tech and Extrusion Technologies by All Extruded

Extrusion

Extrusion

2+ MIN

14/06/2019

Extru-Tech: ADP – Aseptic Dual Preconditioner

The Aseptic Dual Preconditioner enables the operator to incorporate a combination of low steam pressure injected at multiple inlets and adjustable product retention time. This provides the system operator with a whole new level of product quality control. It is the answer to increased nutritional values and production quality. As finished product quality and nutritional values increase, preconditioning is becoming a vital part to any production process. Extru-Tech's Aseptic Dual Preconditioner will enable you to meet these increasing demands as well as provide these benefits: High Liquid Addition Low Energy Consumption Variable Retention Times Low Coefficient of Variation Starch gelatinization levels attainable up to 60% formula dependant Temperature Over 90°C Human Food Hygienic Grade Equipment High meat addition Proven first in first out technology CAPABILITY – ACCURACY & CONSISTENCY As the ADP matches/exceeds the same number of Beater Impacts on Product as our closest competitors' advance technology preconditioner, the ETI best in class ADP often exceeds any competitors' CV. Our studies show that the ADP has a Coefficient of Variation of less than 3%, which means it's more efficient than our competitors latest pre-conditioner designs. The CV improves further as the beater speeds increase through our new design. The ADP features an Automatic downspout with 'Downspout temperature' probe strategically mounted for improved accuracy (per ETI Generic Validation Study) Coefficient of Variation (CV) CV is a measure of precision. ExtruTech's CV Trials tested the accuracy and variability of moisture of the product while exiting the ADP. CLEANABILITY – QUICK CLEAN Why settle for just sanitary when sterile can be achieved? Extru-Tech offers a proven scientific validation that the new ADP can sterilize the product prior to its discharge from the preconditioner, and can be cleaned/sanitized through validated SSOPs. Stainless steel construction and hygienic framework create a sleek exterior design that has no shell or wrap so that it can be easily cleaned and maintain sanitary design standards. The clean-out valve assists with sanitation procedures. by ExtruTech