6+ MIN

17/06/2021

Innovation on the Pet Food and Treat Production with Twin Screw Extrusion

The The planned expansion is based on the global increase in pet adoption, increased awareness of the importance of nutrition for animal health and a continuing trend to view pets as one more member of the family. These patterns have created great opportunities for pet food producers, especially in specialty markets. These include premium, natural, grain-free, organic, or protein-enriched food niches, as well as wellness niches that focus on skin care and allergy management, digestive health, and urinary tract, puppy and kitten care, or senior pet nutrition.

Within these niches, there are also micro-markets for specific activities or breeds of dogs and cats. These opportunities, combined with the emergence of new technologies, enable the levels of creativity and innovation unheard of for pet food and treat manufacturers.

Twin Screw Extrusion Opens a door to New opportunities

Not too long ago, the common practice for pet food production aiming for cats and dogs was to mix basic grains with water, process them in a single screw extruder and coat the finished product with oil, essential and tasty nutrients.

The increasing sophistication of the market and the emergence of more studies supporting the importance of nutrition for dogs and cats - together with the trend towards a humanization of pet food - have led to the adoption of Twin screw extrusion technology replacing single screw extrusion.

This change is explained by various reasons. Twin screw extruders enable complex, high-level processing tasks with precise control of mix intensity and product quality. The twin screw platform offers a greater degree of process flexibility thanks to independent screw speed and production functions, along with the ability to perform several different processing functions at the same time.

We can have a much better control of the processing parameters (including inputs of heat, shear or mechanical energy) improving the quality and consistency of products, as well as protecting volatile ingredients to preserve their effectiveness. The gradual introduction of new ingredients for pet food manufacturing has shown that twin screw extruders can competently process a wide variety of raw materials and mix formulations that are difficult to process in single screw extruders without the aid of equipment. or additional readjustments.

Today, market demands go well beyond the previous "meat-like" requirement. Ingredients in pet food and treats can include vegetables (squash, beans, carrots, or broccoli), alternative proteins (yeast, nuts, algae, or insects), and fruits (blue and lingonberries, melons, or apples). Feed with a high meat content is also very popular. Other areas of opportunity reside in nutraceuticals for pets, capable of providing nutrients, vitamins or medication in an animal-friendly format, as well as meat substitutes.

While these new products can ensure high profit margins, they require scalable and reliable processing with precise process control to protect the integrity of sensitive ingredients. For this reason, the twin screw extruder has become an indispensable tool for pet food manufacturers who want to meet the demands of those "pet parents" looking for premium pet foods and treats with clear labels, healthy ingredients, advanced nutrition and miscellaneous attributes that mimic the quality and visual appearance of human food.

Development of New Products for specialized Markets

It is important that producers take into account the niche market they are targeting before developing their products to design ones that are attractive according to the preferences of pet owners. In today's marketplace, pet food and treats are expected to offer animal welfare benefits, healthy ingredients, and quality protein sources.

Niche products have additional requirements that require testing, evaluation and refinement of recipes and ingredients during the R&D process. A conventional R&D center will handle design, laboratory testing, prototyping, small-scale batching, and industrial simulation.

In this process, the twin screw extruder offers the flexibility to quickly change production parameters (screw configuration, barrel length, residence time, shear, expansion) and process controls (liquid and vapor injection, flow channels). heating and cooling) to quickly adjust the properties of the products.

This also allows tests to be completed with the least possible residue, which is an important factor when working with high-quality ingredients, vitamins or nutraceuticals. Furthermore, while real-time operating conditions can be monitored from the operator panel, all data is logged for future review and analysis.

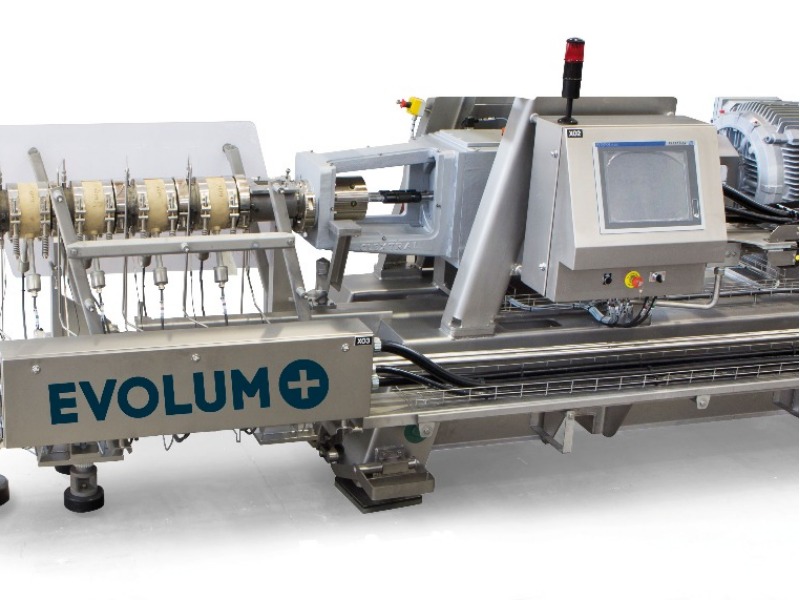

Twin screw extruders often have features that make it easy to access the product and clean (Clextral has automatic barrel opening) to, in addition to saving time, allowing developers to effectively test various recipes in each rehearsal session. This flexibility will also benefit manufacturers when products are moved into a real production environment, as it will allow the processing of several different products on the same production line and extruder with minimal downtime for product changes. A key advantage for supplying products to small niche markets.

From the Laboratory to the Production line

After a product has been developed in the test center, scaling is a critical step to ensure that the product derived from the extruder on the production line exhibits the same attributes as the product derived from the R&D unit. Therefore, the design of the extruder is an important factor.

Clextral extruders feature proven homothetic designs to ensure predictable scaling. Producers should rely on the specialized knowledge, experience, technical assistance and training provided by their extrusion equipment suppliers to optimize product quality and consistency on the production line. These extrusion experts are continually testing and improving processes and recipes to support their customers, so they should be seen as key players on the development team.

Preconditioners improve Product Quality and increase Production

Preconditioners have long been used to increase extruder output by pre-processing the grain and initiating the gelatinization of the starch. This process decreases the required residence time within the extruder for a higher production volume with less wear and tear on the equipment. Today, preconditioners are used to offer additional benefits:

• Initial mixing of all ingredients to ensure uniform distribution and hydration before extrusion.

• Improved thermal energy transfer to the product to preserve its nutritional properties.

• In the case of products with a high meat content, the introduction of the meat in the preconditioner provides a longer residence time for mixing with the dry ingredients in order to ensure the homogeneity of the products.

Twin Screw Extrusion Technology can meet present and future needs

Twin screw extrusion offers numerous advantages for pet food producers, as this technology provides a complex mixing and processing system for the production of sophisticated products within a hygienic, flexible and infinitely repeatable platform. In addition, considering that the market is constantly evolving, the twin screw extruder can be easily reconfigured for the processing of new products that meet consumer expectations. Key benefits:

Greater consistency in production and product quality control.

Maximum productivity thanks to continuous processing, more agile startup and shutdown between faster product changes, and advanced automation.

Unbeatable flexibility with the ability to process a wide variety of raw materials.

Optimized environmental impact thanks to saving water and energy.

Simple and easy maintenance and cleaning.

How to Succeed in Specialty Pet Food and Treat Markets

It is important to study trends, consumer wishes, and competition to determine those products that the pet food market demands at all times. A healthy food or treat does not guarantee success if it does not satisfy the needs or attract the interest of the consumers to whom it is directed. With the twin screw extrusion platform, producers have flexible development and production tools capable of optimizing their processes and facilitating their adaptation to changing market needs.

This technology not only enables producers to capitalize on emerging trends and opportunities, but also ensures their reactivity to succeed in the Pet Food market.

Author: Hadrien Delemazure - Feed Extrusion Expert

Source: Clextral Inc.