ANDRITZ

http://www.andritz.com/

ANDRITZ

About company

With over 180 years of industry experience, no one knows more about these opportunities than ANDRITZ.

We are one of the world's leading suppliers of advanced industrial technologies, systems, services and equipment for the animal, fish and pet food sector, as well as for biofuel pelleting.

Our knowledge, services and solutions continue to drive the evolution of animal feed and biofuel production of the future.

SERVICES WE OFFER

- Solutions for processing lines

- Individual machines

- Technical consultancy

- Engineering services

- After-sales service and assistance

Products

Company News

Extrusion

Extrusion

4+ MIN

03/01/2024

Raising the Bar in Pet Nutrition: ANDRITZ's Twin-Screw Extruders for High-Meat Formulations

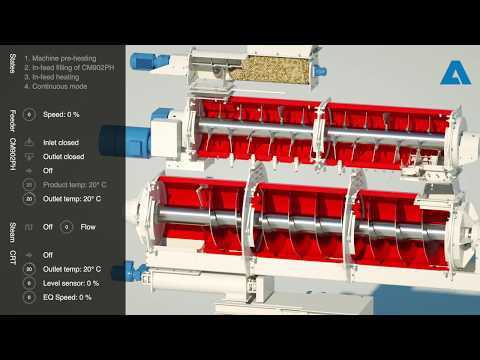

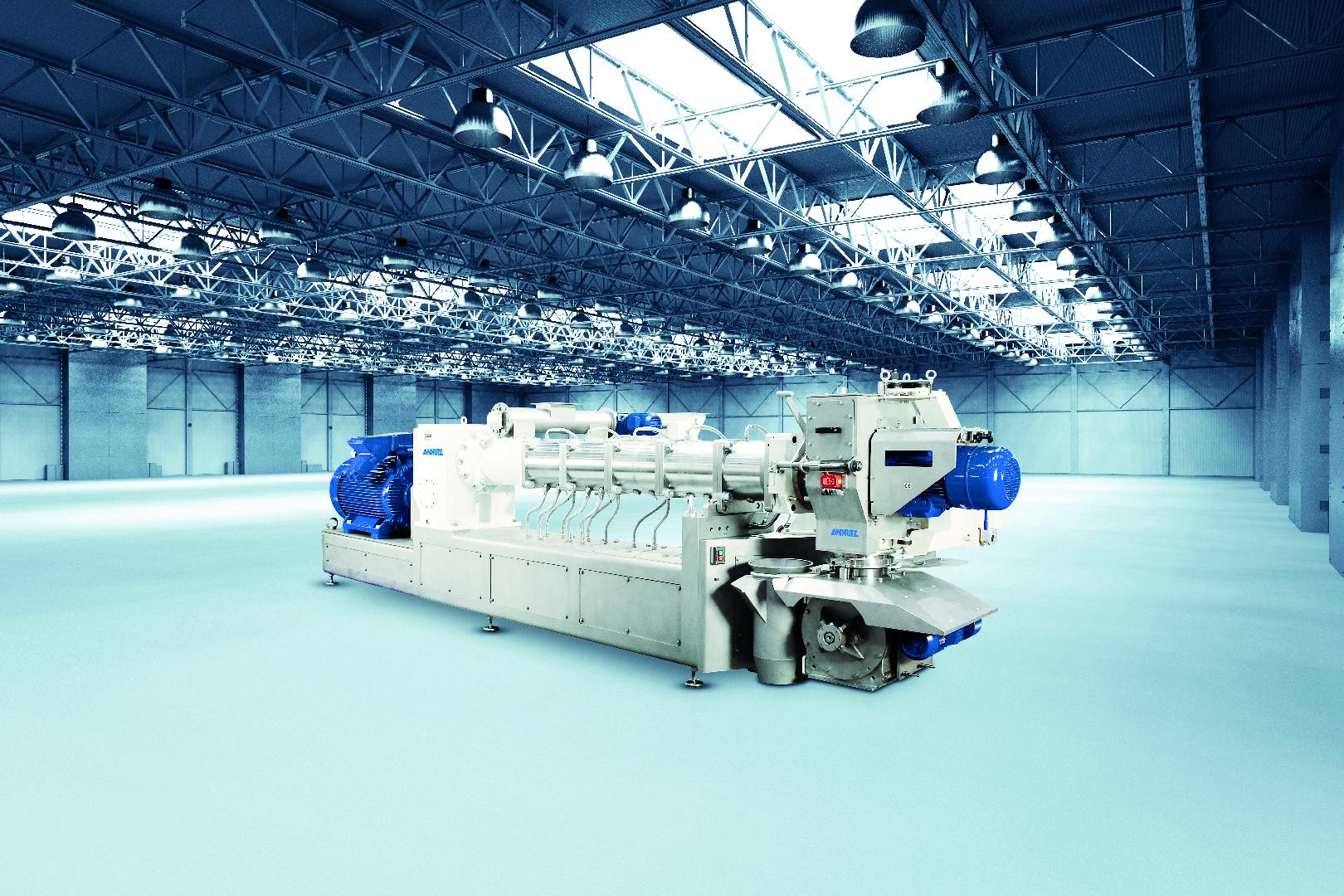

The Rise of High-Meat Pet Food Pet owners today are becoming more mindful of what goes into their pets' bowls, and the high-meat pet food trend is a result of this growing awareness. High-meat pet food refers to formulations that contain over 30% fresh meat content. This demand stems from a desire for better digestibility and premium nutrition for pets. However, this shift presents its own set of hurdles, particularly in achieving the right cooking temperatures due to the moisture and fat content in raw animal ingredients. Challenges in High-Meat Pet Food Production Creating high-meat pet food formulations comes with unique challenges. The variability in raw animal ingredients complicates the manufacturing process, demanding careful handling to maintain consistency. As Niels Bengt, Sales Director KA, LATAM at ANDRITZ, explains, "Dealing with the diversity of raw animal ingredients requires innovative solutions to ensure uniform processing, which is vital for preserving the nutritional quality of the final product." As a result, the production of high-meat pet food often requires the employment of twin-screw extruders, known for their superior capabilities compared to single-screw counterparts. These extruders offer advanced kneading and mixing capabilities, pivotal for upholding the desired texture in high-meat formulations. Yet, the pursuit of elevated throughput rates while adhering to compact machine dimensions adds an additional layer of complexity to the manufacturing process. Striking the Balance Between Efficiency and Nutritional Integrity In the face of these challenges, ANDRITZ's twin-screw extruders, ExTS 616 & 718, emerge as a transformative solution for high-meat pet food production. Specifically designed to excel in extruding pet food enriched with elevated meat inclusion ratios, ANDRITZ's twin-screw extruders ensure optimal starch utilization, affording unparalleled formulation flexibility and optimized feed conversion ratios. The synchronized, high-shear twin screws guarantee the complete material discharge, minimizing waste and expediting recipe transitions. "Our twin-screw extruders are crafted to tackle the intricacies of high-meat pet food production. We are resolute in our commitment to efficiency while upholding nutritional integrity. ANDRITZ's twin-screw extruders stand as the definitive solution that not only meets but surpasses the challenges of high-meat pet food production," says Niels Bengt, Sales Director KA, LATAM at ANDRITZ. "Our approach is centered on achieving a harmonious synergy between the seamless functioning of our machines and the preservation of the vital nutrients within high-meat formulations. With precise control over cooking temperatures and meticulous handling of diverse ingredients, our twin-screw extruders stand as a testament to our dedication to delivering pet food that not only excels in quality but also upholds the nutritional essence of each ingredient," Niels Bengt adds. This distinctive approach has been expertly crafted to tackle head-on the intricate challenges that arise from incorporating raw animal ingredients into recipes. By providing pet food producers with meticulous control over cooking temperatures, ANDRITZ's solutions effectively address the nuances associated with different ingredients, ensuring that each element is handled appropriately. This attention to detail serves as the linchpin for safeguarding the nutritional richness present in high-meat pet food formulations, ultimately resulting in a final product that not only offers exceptional palatability but also remains an optimal source of nourishment for our loyal animal companions. From Conscious Consumers to Circular Economy Moreover, as societies worldwide increasingly embrace environmental consciousness, consumer interest in the food supply chain has surged due to growing sustainability concerns. Transparency in sourcing and production is no longer sufficient; consumers now demand an understanding of how food production impacts the planet. This scrutiny extends even to pet foods and treats. As the world transitions toward a circular economy, driven by the urgency to mitigate greenhouse gas emissions and reduce landfill waste, it's essential to recognize the role of rendering as a form of recycling. Rendered ingredients include proteins sourced from animal muscles, organs, and bones not suitable for human consumption but perfectly safe for animals. This holds particular significance as approximately 50% of an animal is unsuitable for human consumption, and without rendering for alternative uses, this portion would go to waste. Therefore, integrating fresh meat into pet food aligns with the principles of the circular economy, promoting resource efficiency. ANDRITZ's twin-screw extruders play a significant role in advancing this circular economy in the pet food industry. By efficiently processing raw animal ingredients and minimizing waste, ANDRITZ machines contribute to a more sustainable pet food production process, while maintaining the nutritional quality that pets deserve. The Way Forward: Nourishing Pets and the Planet Simultaneously As the pet nutrition industry evolves, the high-meat pet food trend poses challenges that require innovative solutions. ANDRITZ rises to the occasion, ensuring efficient processing of fresh meat ingredients while upholding their nutritional value. Beyond efficiency, ANDRITZ's twin-screw extruders exemplify a commitment to sustainability, ushering in a more environmentally conscious era for pet food manufacturing. Niels Bengt, concludes, "Our solutions not only address the demands of the pet food industry but also contribute to a more sustainable future. By providing highly efficient machinery that produces high-quality, high-meat pet food, we're meeting the needs of pets, their caring owners, and our planet." In the future, ANDRITZ aims to continue pushing the boundaries of innovation to further enhance pet food production. "Our innovations are not just products; they are promises of a brighter, more exciting future for our customers." Source: All Pet Food Magazine

Manufacturing Process

Manufacturing Process

3+ MIN

10/11/2023

ANDRITZ and Pet Food Innovation

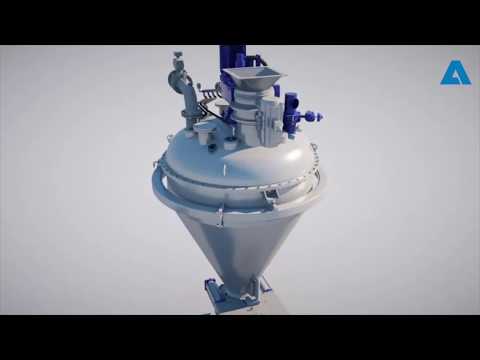

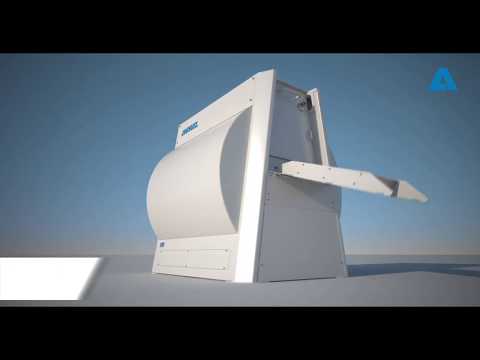

ANDRITZ and the Future of Pet Food: Innovation and Sustainability at the Forefront The pet food market is constantly evolving, and the increasing demands require advanced processing technology solutions. ANDRITZ, as a trusted partner for hundreds of premium pet food producers globally, is at the forefront of this revolution. In a world where sustainability and digitalization are redefining industries, ANDRITZ stands out for its focus on both areas. The company not only commits to excellence in performance and quality but also prioritizes innovation and technological development. This is reflected in their goal to offer advanced technologies that result in efficient production, operational cost reduction, maximum energy efficiency, and environmental protection considerations. Backed by global specialists, ANDRITZ offers comprehensive solutions for pet food pelletizing, ensuring easy, safe, and efficient processes that quickly adapt to market trends. From raw material intake to the loading of finished foods, ANDRITZ equipment and systems stand out for their cutting-edge technology. These processing systems provide optimal results in food safety and traceability, ensuring both animal health and regulatory compliance. However, beyond technological solutions, ANDRITZ understands the importance of management and collaboration. With over 180 years of experience and a vast sales and service network globally, the company ensures a close and cooperative relationship with its clients. ANDRITZ's solutions are tailor-made, specifically designed to meet high production capacity and quality demands. This adaptability is made possible thanks to modular systems and multiple design features combined with specialized engineers' expertise. Process automation, another pillar of ANDRITZ, guarantees cost-efficient processing and consistent food quality. These automation systems offer complete traceability of ingredients and process parameters and represent a perfect fusion between technology and efficient operation. At the end of the day, ANDRITZ's promise is clear: "You know your product, we know productivity." With state-of-the-art technologies and a deep understanding of every process step, ANDRITZ positions itself as the undisputed leader in pet food processing solutions. ANDRITZ's Highlighted Technologies for Premium Pet Food Production VAC 1000/1500 for Super Premium Food: Precise control in the inclusion of high-cost liquids and powders, achieving significant savings in the pet kibble manufacturing process. Uniform coating across all kibbles batch by batch. Possibility of a higher inclusion of oils when using vacuum vs. the natural limitation of working at atmospheric pressure. Both appearance and end-product quality superior vs. other solutions like rotary coaters. Possibility to create new formulations and products due to the wide working range our VAC model oilers allow. Double Screw Extruder ExTs 616/718: Superior cooking control vs. single screw by achieving full starch utilization. Greater control and flexibility in the formulation by including a higher % of fresh meat or slurry. Superior mixing inside the extrusion barrels. Higher hygiene as it's self-cleaning. Greater working range in moisture percentage inclusion. Greater working range in fat percentage inclusion. CZD High-Efficiency Dryers: Independent drying control in each CZD zone. The market's lowest humidity dispersion percentage upon exiting the dryer, achieving less or equal to 0.5%. Modular dryer, so for future higher requirements, the dryer can be expanded. Controlled and even product bed filling thanks to the. Significant energy savings due to air recirculation, temperature and exhaustion relative humidity control. Thanks to CZD's advanced automation control, it's possible to know in real-time the energy consumption associated with product drying. ANDRITZ continues to innovate and adapt to the changing demands of the pet food market. With its focus on sustainability and technology, the company is positioned to continue leading in this field in the coming years. By: ANDRITZ